Biomedical Engineering Reference

In-Depth Information

(a)

(b)

(c)

(d)

Figure12.3

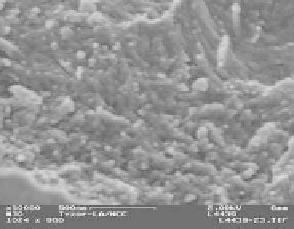

FESEMimagesof (a)as-preparedand(b) calcinedTyzor-LA-CNXLcomposite,

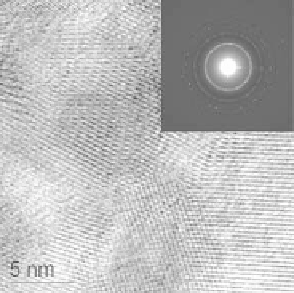

andTEMimages(c)correspondingtitaniaproductand(d)high-resolutionTEMimagesof the

titania (inset: selectedelectrondiffractionof titania) (reprintedwithpermission fromref 24).

Copyright2007Elsevier.

and 5-10 nm in diameter. After calcination, it is difficult to discern CNXL-shaped

titania due to thermal collapse. It is apparent that Tyzor-LA-CNXL composites under-

went serious shrinkage during the calcination process. A few aggregated titania showed

CNXL-shapes. TEM images and selected area diffraction pattern (SEAD) were employed

for further determination of the morphology and orientation of the titania. In TEM

images, there are many channels with irregular diameters connected together, which have

been generated by CNXL templates. After thermal treatment, collapsed CNXL-shaped

pores are mesoporous, which are marked with arrows in Figure 12.3c. High resolution

TEM image (Figure 12.3d) shows nanocrystalline anatase lattice. An electron diffraction

pattern recorded on a titania surface has clear diffraction rings that correspond to the

anatase phase of titania. Titania products are clusters of 5-7 nm nanocrystalline anatases.

BET results (not shown here) indicate that titania samples have 170-200 m

2

/g of specific

surface area and irregular pore diameters after calcination at 500

◦

C in air. In addition,

titania samples showed high stability without changing morphology and crystallinity in

harsh media such as conc. HCl, HNO

3

, and dil. H

2

SO

4

. This novel titania material with

Search WWH ::

Custom Search