Biomedical Engineering Reference

In-Depth Information

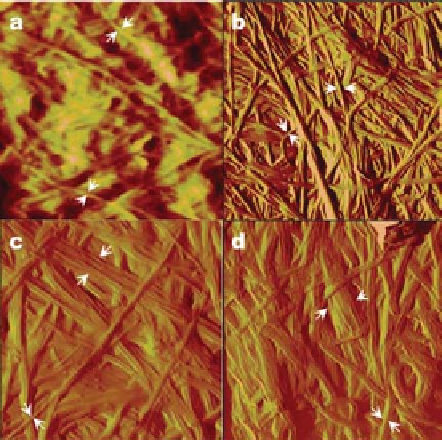

Figure 9.27

Atomic Force Microscopy Images of BC grown in (a) HS medium, (b) HS

mediumwith 1% PEO, (c) HS medium with 3% PEO, and (d) HS mediumwith 5% PEO

(68).(ReprintedwithpermissionfromBrown,E.E.;Laborie,M.-P.G.,Bioengineeringbacterial

cellulose/poly(ethylene oxide) nanocomposites. Biomacromolecules, 2007, 8, 3074-81.

Copyright(2007),AmericanChemicalSociety.)

10

9

10

8

10

7

59:41

53:47

33:67

23:77

15:85

0:100

10

6

10

5

10

4

10

3

−

60

−

40

−

20

0

Temperature (

20

40

60

80

100

°

C)

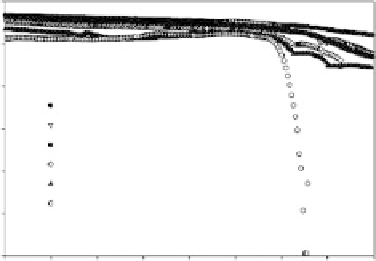

Figure 9.28

Storage tensile modulus E' versus temperature at 1 Hz for nanocomposites

of varying BC/PEO ratios (68). (Reprinted with permission from Brown, E.E.; Laborie,

M.-P.G.,Bioengineeringbacterialcellulose/poly(ethyleneoxide)nanocomposites.Biomacro-

molecules,2007,8,3074-81.Copyright(2007),AmericanChemicalSociety.)

various water-soluble polymers including poly(vinyl alcohol). It appeared that PVA was

easily washed from the BC/PVA nanocomposite during the purification step although

some PVA could be detected when 2% PVA was added in the growth medium of BC. In

this case, the BC network structure and crystalline structure appeared to be unaffected by

the presence of PVA. This contrasted with the morphology of the BC/methyl cellulose

Search WWH ::

Custom Search