Biomedical Engineering Reference

In-Depth Information

0.5

m

0.5

m

µ

µ

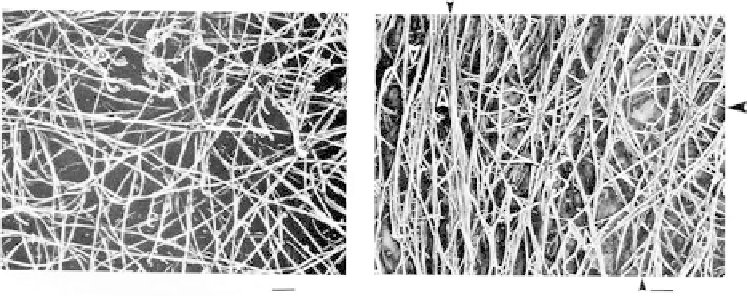

Figure 9.18

Micrographs of cellulose ribbons obtained in standard growth

conditions-control BC (left) and obtained in presence of Xyloglucans-BC/xyloglucans

nanocomposites (right). (Whitney, S.E.C.; Brigham, J.E.; Darke, A.H.; Reid, J.S.G.; Gid-

ley,M.J., In-vitroassemblyof cellulose/xyloglucannetworks-ultrastructural andmolecular

aspects.Plant Journal,1995,8(4),491-504.Copyright1995,Reprintedwithpermissionfrom

Wiley-Blackwell.)

system only exhibited the mobile xyloglucan cross-bridges, clearly illustrating the poten-

tial of biomimetic approaches to develop nanocomposites with unique morphologies (65).

When the small deformation rheological properties of the intact and pulverized

BC/xyloglucan nanocomposites were compared to those of tomatoes' primary cell

wall and of BC alone, striking similarities were observed (66). Namely, the dynamic

viscosity, storage (G') and loss (G”) shear moduli followed similar trends in the tomato

cell wall, pulverized bacterial cellulose and in BC/xyloglucan nanocomposites (66) with

a noteworthy solid-like behavior. Hence it was proposed that under small deformation

the entangled cellulosic rods rather than the xyloglucan crosslinks dominated the

shear moduli of these nanocomposites. Cellulose was therefore the key mechanical

component that contributed to the linear viscoelastic behavior of BC/xyloglucan

nanocomposites. In contrast xyloglucans appeared to play a significant role in the

nonlinear uniaxial tensile properties of BC/xyloglucan nanocomposites (66). When

tested under hydrated conditions, BC sheets were stiffer, stronger but less extensible

than BC/xyloglucan sheets (all with less than 10% cellulose content) (Figure 9.20). This

mechanical response was rationalized in terms of the different entanglements in BC

and in the BC/xyloglucan nanocomposite (66) and in a later publication modeled based

on small-angle X-ray scattering experiments performed during uniaxial loading tests

(58). Namely, it was proposed that in the randomly oriented fibers of neat BC, looped

links required more force and allowed low stretching before failure (Figure 9.19).

Alternatively, alignment of cellulose ribbons in the BC/xyloglucans nanocomposites

generated entanglements between somewhat parallel fibrils. Upon uniaxial loading the

ribbons or crosslinked domains could orient with the loading direction until the breaking

point at a large extension (Figure 9.19). These concepts would explain the lower

tensile strength and stiffness and higher extensibility of BC/xyloglucan nanocomposites

compared to neat BC in uniaxial tensile loading.

Search WWH ::

Custom Search