Biomedical Engineering Reference

In-Depth Information

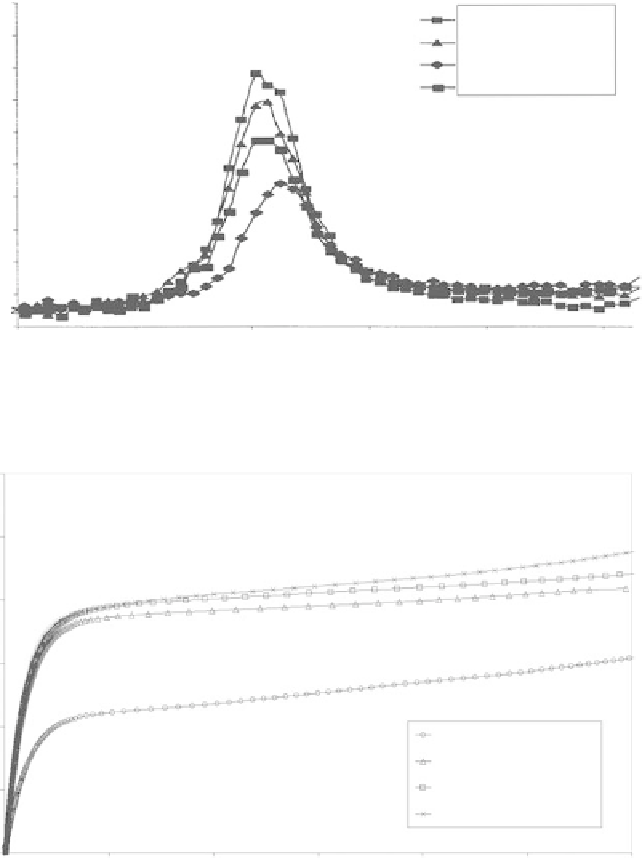

0.5

Pure Matrix

10% filler

30% filler

20% filler

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

−

80

−

60

−

40

−

20

0

20

Temp

°

C

Figure8.16

Tan

δ

plotsfortheneatplasticandthereinforcedcomposites.

6.0

5.0

4.0

3.0

2.0

Cellulose Nonanoate

Cellulose Nonanoate + 5 % C9

Cellulose Nonanoate + 10 % C9

Cellulose Nonanoate + 15 % C9

1.0

0.0

0

20

40

60

% Strain

80

100

120

Figure 8.17

Stress-strain curves for the C-9 cellulose ester reinforced with C-9 surface

derivatizedchitinnanoparticles.

behavior marks the yield stress. It is also observed that much of the mechanical rein-

forcement gained is achievable with only 5 wt% filler loadings. The mechanical data

provided for both cellulose and chitin nanoparticles demonstrates that these biomaterials

have great potential for providing mechanical reinforcement to elastomeric thermoplastics

when used as filler materials in composite applications.

Search WWH ::

Custom Search