Biomedical Engineering Reference

In-Depth Information

µ

f

(

×

10

5

)/Nm

−

2

h

f

(10

−

3

)/Nm

−

2

2.5

2.0

Ubl TMP

high I

Ubl TMP

high I

1.8

2

Bl TMP

low I

Xylan

low I

1.6

Ubl TMP

low I

1.5

Bl TMP

low I

1.4

Xylan

low I

Ubl TMP

low I

1

1.2

1.0

0.5

50

100

150

200

250

50

100

150

200

250

Time (min)

Time (min)

(b)

(a)

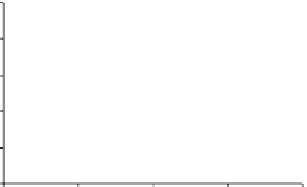

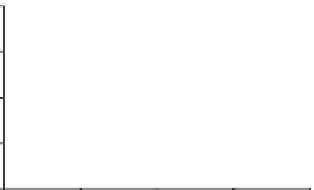

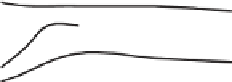

Figure 6.5

Variations in (a) shear viscosity and (b) shear elasticmodulus as a function of

timecorrespondingtothebestfittingsbasedonVoigtmodel foraviscoelasticsolid.

unbleached TMP at low (a) and high ionic strength (b) on cellulose. Similar fittings

were carried out for dissolved hemicelluloses isolated from peroxide bleached TMP at

low ionic strength (I

10 mM) and xylan at low and high ionic strength at pH 10

(fitting data not shown). In spite of the simplicity of the Voigt model and a very strong

approximation of its contributions to the elastic properties of an adsorbed polymer layer,

the fitting to the frequency and dissipation data was reasonable. Only the modeling of

xylan layer properties at high ionic strength failed.

The development of the hemicellulose layers shear viscosities (

η

f

) and shear modulus

(

µ

f

) values during the adsorption process estimated by the application of the Voigt

model is shown in Figure 6.5.

The shear viscosity of the formed hemicellulose films stayed more or less at the same

level showing a slightly decreasing trend as the film formation proceeded for all the

systems except for the dissolved hemicelluloses isolated from unbleached TMP at high

ionic strength, which stayed constant. The shear elastic modulus was highest for the

layer of dissolved hemicelluloses from unbleached TMP at high ionic strength and lowest

for xylan layer at low ionic strength. The layer formed by adsorbing peroxide bleached

TMP hemicelluloses showed relatively high shear elastic modulus values. According to

these results, the hemicelluloses isolated from unbleached TMP at high ionic strength

seemed to be most strongly bound on cellulose. Surprisingly the xylan layer at low ionic

strength appeared to be rather loosely bound on cellulose. Furthermore, it can be noted

that the Voigt model failed when the xylan film was modeled at high ionic strength. The

reasons for the low shear viscosity and low shear elastic modulus are discussed later.

The estimated hydrodynamic thickness of the hemicellulose films as the adsorption

proceeds is plotted in Figure 6.6. At the end of the adsorption process the film thickness

of dissolved hemicelluloses at low ionic is approximately 4 nm and at high ionic strength

the final thickness is 9 nm. The hemicellulose film isolated from peroxide bleached

TMP has a final thickness of roughly 2 nm.

=

The xylan film reaches a final thickness

value of 4 nm.

Search WWH ::

Custom Search