Biomedical Engineering Reference

In-Depth Information

40

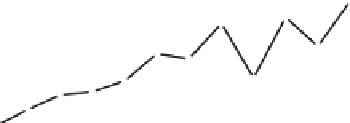

Tensile index, PDADMAC/PSS, 30 k/80 k

Tensile index, PDADMAC/PSS, >500 k/1000 k

8

35

7

30

6

25

5

20

4

15

3

10

2

5

Strain at break, PDADMAC/PSS, >500 k/1000 k

Strain at break, PDADMAC/PSS, 30 k/80 k

1

0

0

0123456789 0 1 2

Number of layers

Figure5.16

TensileindexandstrainatbreakforsheetsmadefromfibrescoatedwithPEMof

PDADMAC30kandPSS80k,presentedasafunctionofthenumberofadsorbedlayers.The

data for highmolecularmass PDADMAC (

>

500 k) andPSS (1000k), taken fromLingstrom

etal.(29),areincludedinthefigureforcomparison.

11 layers were adsorbed, but significantly lower, 25%, for the same number of layers

of the low molecular mass combination (35). A significant result was also that both

systems showed a larger improvement in paper tensile index when the cationic polymer

was in the outermost layer.

The difference in strength-enhancing efficiency between the different polyelectrolyte

combinations and between the conditions during preparation of the PEM can naturally

be linked to the amount of polyelectrolyte adsorbed and to the properties of the adsorbed

layers. The effect on the strength-enhancing efficiency of the charge of the polyelec-

trolyte used in the most external layer must be linked to the properties of the adsorbed

layers since the amount of polyelectrolyte is increased also when the anionic polyelec-

trolyte is added. It is not, however, possible to elucidate the molecular mechanism solely

from the evaluation of fibre network properties, and this is discussed further in the next

section.

The adsorbed amount will naturally have a considerable influence on the strength-

enhancing efficiency of the various chemical combinations, and in Figure 5.17 different

chemical systems are compared as a function of the adsorbed amount of chemicals (48).

Efficiency, on the basis of the adsorbed amount, is clearly highest for the combina-

tion of amylose-rich cationic starch and anionic starch and efficiency is lowest for the

combination of cationic potato starch, cationic amylopectin starch and anionic starch.

It is also obvious that the differences between the systems are rather large for a given

adsorbed amount. This indicates either that the adhesive properties of the layers are

significantly different or that the ways in which the chemicals affect the joint-forming

mechanism between the fibres in the fibre network are very different. The results show

considerable promise for the PEM technology for fibre and sheet engineering, and they

also indicate that the selection of chemicals and how they are added are of paramount

importance if the changes desired with the added chemicals are to be achieved.

Search WWH ::

Custom Search