Biomedical Engineering Reference

In-Depth Information

the shear viscosity

η

eff

and moduli

G

and

G

became quite different from those of

the bulk. On entering the tribology regime (film thickness

<

30 nm) PBD exhibited

highly nonlinear behavior and yield points indicative of phase transitions to 'glassy'

or 'solid-like' states. Klein

et al

. (Klein and Kumacheva 1998) discovered that the

transition between liquid-like behavior and a solid-like phase of the liquids under pro-

gressive confinement take place abruptly at a distance of few molecular layers. The

films that are thinner behaved in a solid-like fashion and they required a critical stress to

shear them.

4.6.2

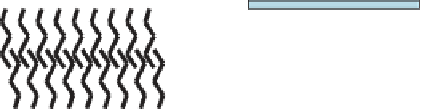

Orientation of Lubricant Films

Why can lubricants reduce friction? How do lubricant molecules work and behave under

shear? These questions are currently being investigated by several groups. Lubricant

molecules organize themselves under shear as illustrated in Figure 4.7 by Yoshizawa

et al

.

(Yoshizawa, Chen

et al

. 1993). A critical velocity

V

c

* exists; if the sliding velocity of

two surfaces are below

V

c

* a polymeric lubricant film exhibits amorphous structure and

the polymer chains interplay and entangle with each other. In this case high friction is

produced (static-kinetic sliding). This phenomenon supports experimental observations

in which chain interdigitation was found to be an important molecular mechanism giving

rise to 'boundary' friction and adhesion hysteresis of monolayer-coated surfaces. If the

sliding velocity of two surfaces is above the critical velocity, polymer chains will be

aligned or 'combed' by shear into an ordered conformation and therefore will result in

very low friction (superkinetic sliding).

The phenomenon of shear-induced alignment of lubricant molecules has been vali-

dated by a number of experiments. For example, Frantz and co-workers (Frantz, Perry

et al

. 1994) adsorbed polyisoprene onto a single solid surface and found that the back-

bone of the polymer oriented in the direction of flow. They also found that the extent

of orientation increased with increasing molecular weight. The structure of the lubri-

cant, such as chain length (Frantz, Perry

et al

. 1994), packing densities (Ruths 2003;

Ruths, Alcantar

et al

. 2003), and nature of the polymer (brush-like (Zappone, Ruths

et al

. 2007) or grafted polymer (Urbakh, Klafter

et al

. 2004) and chain ends (Chen,

Maeda

et al

. 2005)) have been found to influence molecular alignment of the lubricant

under shear.

Within these investigations, the work of Urbakh

et al

. (Urbakh, Klafter

et al

. 2004)

is very significant. They used grafted polyelectrolytes, hyaluronan and hylan, to mimic

V

<

V

c*

V

>

V

c*

D

Static-kinetic sliding

Superkinetic sliding

Figure4.7

Lubricantmoleculesorganizedbyshear.ReprintedfromYoshizawa,Chenetal.

Copyright(1993)withpermissionfromElsevier.

Search WWH ::

Custom Search