Agriculture Reference

In-Depth Information

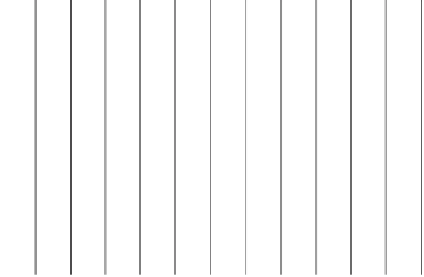

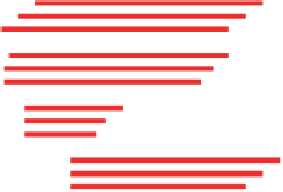

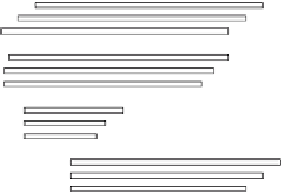

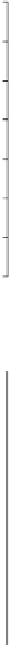

%HVW'XWFK&XOWLYDU

VFHQDULR

%UHDNHU

3LQN

5HG

VFHQDULR

ŮŜŐŚƚĎŮƵĞ

ϮΣ

%UHDNHU

ĎŮƵĞ

ΚΣ

3LQN

ŐƋĞĞŶ

ϬϹΣ

5HG

ƉƵƋƉŮĞ

ϬϴΣ

VFHQDULR

LJĞŮŮŽǁ

ϮΡΣ

%UHDNHU

ƉƵƋƉŮĞ

WĎĞĨŽƋĞƐƵƉĞƋŴĂƋŬĞƚ

3LQN

5HG

ƋĞĚ

WŜŶƐƵƉĞƋŴĂƋŬĞƚ

VFHQDULR

%UHDNHU

3LQN

5HG

:RUVW'XWFK&XOWLYDU

VFHQDULR

%UHDNHU

3LQN

5HG

VFHQDULR

%UHDNHU

3LQN

5HG

VFHQDULR

%UHDNHU

3LQN

5HG

VFHQDULR

%UHDNHU

3LQN

5HG

6XSSO\FKDLQGD\V

Fig. 14.3

Scenario analysis of the best and worst Dutch tomato cultivar with regard to the start and

the duration of the acceptance period. (Schouten et al.

2010

)

Table

14.2

presents an overview of improvement opportunities when implement-

ing the QCL concept in the tomato and mango supply chains.

Case Study in the Mango Supply Chain

The Mango Supply Chain

Typically, mango fruits are picked in an unripe stage in tropical or sub-tropical

countries and cooled during weeks of sea transport in reefers to slow down the

ripening process. Most mangoes are harvested when they reach a sufficient size