Agriculture Reference

In-Depth Information

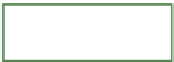

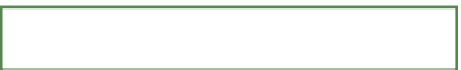

QCL-elements

Operational requirements

1. Consumer

preferences & product

acceptance period

•

Understand consumer preferences of quality attributes

•

Get insight in product acceptance period for all market segments

•

Get insight in dynamic behaviour of product quality attributes

•

Systematic assessment of CQPs that have major impact on

product quality & availability in retail outlets

2. Critical quality

points (CQP) for quality

and logistics

•

Have ability to measure & analyse quality at CQPs

•

Have automated quality measuring at CQP‛s

•

Have prediction models to calculate real product quality

3. Product quality

measurement and

prediction

•

Use advanced data loggers and techniques (RFID,GPS) to capture

relevant information real-time & reliable

•

Exchange quality, supply and demand information in chain

4. Data logging and

exchange of

information

•

Set local targets for quality attributes, reduce variability inte-

nally and manipulate product quality in line with market demands

•

Apply quality driven inventory management principles

•

Sort for homogeneous small batches, have quality based order

picking and transport (matching delivery with consumer wishes).

5. Local dynamic/

adaptive logistics and

quality control

•

Establish full chain collaboration to create demand-driven chains

•

Direct goods to highest value markets and apply efficient

replenishment and JIT principles for responsive distribution

•

Use temp. controlled reefer containers and packaging with MA

6. AgriFood Supply

Chain Management

Fig. 14.1

Operational requirements of QCL elements

and with RQFO exactly that batch is delivered, which has the right quality for that

particular customer.

f. Supply Chain Management (SCM)

Finally, all SCM practices as discussed earlier (like CPFR, VMI) can be applied in

the complete supply chain to match supply and demand using the advanced product

information exchanged in the supply chain and collaborative logistics decision poli-

cies; production and distribution lead times can be shortened, full chain transpar-

ency created and waste and costs reduced.

These six elements can be combined in a preliminary diagnostic instrument that

indicates the operational requirements of each QCL element (see Fig.

14.1

). The

next step is to develop different performance levels to assess specific supply chains

and to analyse the relationship between QCL elements and supply chain perfor-

mance. To get some first insight in this the next sections describe case studies in the

tomato and mango supply chain network.