Chemistry Reference

In-Depth Information

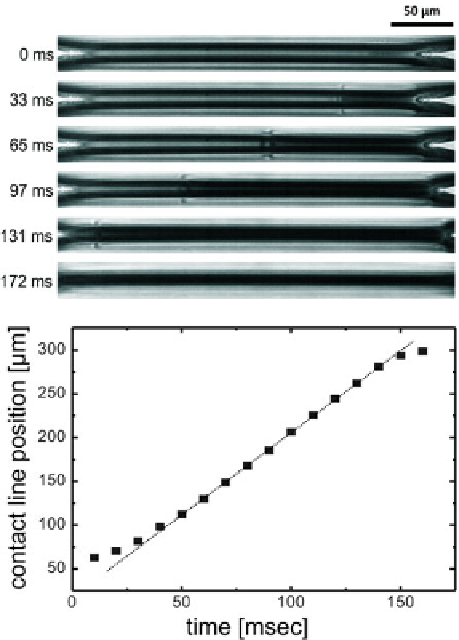

Fig. 2.7

Time-resolved

micrograph of membrane

formation in a micro-fluidic

system.

To p

time-lapse images

of three-phase contact line

moving across the oil lamellae

while membrane is form-

ing. The total diameter of

the membrane is 300

m.

Bottom

Three-phase contact

line position as a function of

time. The slope of the

dotted

line

is 1.9mm/s

µ

constancy of the contact line velocity (i.e., the first derivative of the diameter with

respect to time) suggests a constant power of dissipation, which is due to the viscous

friction in the vicinity of the edge of the membrane, where the two aqueous phases

and the oil phase meet. More specifically, we can compare the contact line velocity

of about 1.9mm/s with the capillary velocity,

v

c

=

γ/η

=

is the

viscosity of the liquid (in this case Squalanewhich has a viscosity of 43.4mPa.s). This

is a natural velocity scale for the system, corresponding to the balance of interfacial

and viscous forces. Clearly, the measured contact line velocity is much less than

v

c

,

which can be attributed to the diverging viscous stress near the three-phase contact

line [

24

].

For an effective manipulation of the droplet configuration within the micro-fluidic

setup, it may be necessary to move the emulsion through the micro-fluidic device.

This can be done either externally by pressure or volume control (e.g., syringe

pumps), or internally by means of suitable local mechanisms. In any case, it is

of central importance that these manipulation steps do not lead to the destruction

of membranes. One might anticipate that this constraint poses a serious conceptual

4

.

1 cm/s , where

η