Environmental Engineering Reference

In-Depth Information

Table 10.5 Chip-sized electrocaloric cooling device and its properties

Name and address of institute

The Pennsylvania State University

Name of contact person/email

Qiming Zhang

qxz1@psu.edu

Year of production

2012

Maximum frequency

1 Hz

Maximum cooling power

N/A

Maximum temperature span

6.6 K

EC material

High-energy electron-irradiated

P(VDF-TrFE) 68/32

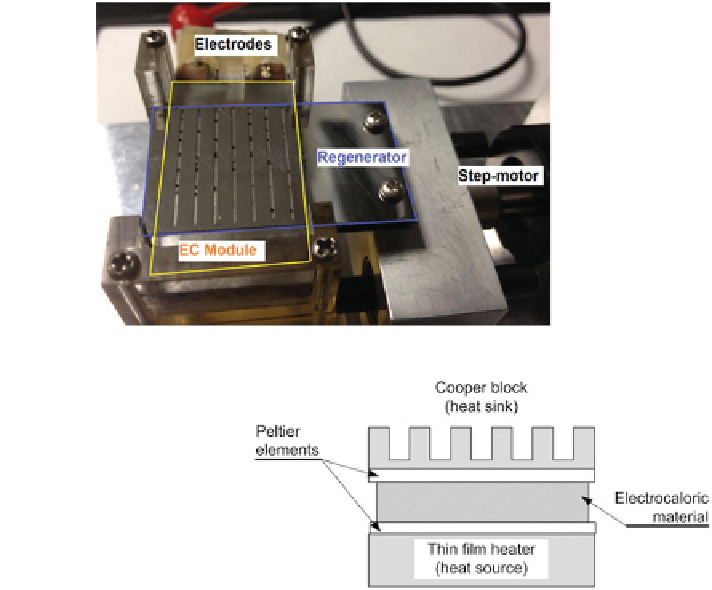

Fig. 10.13 Electrocaloric

cooling device by Chukka

(see also [

55

])

sink. On the bottom side, a thin-

lm heater with 10 W of power (heat source) was

positioned. Additional temperature sensors were inserted between the thin-

lm

heater and the electrocaloric material and between the electrocaloric material and

the copper block. In the

rst-case scenario, the device was heated up to 85

°

C (by

turning on the thin-

lm heater). Then the heater was turned off and the time needed

for the sandwich-like structure to cool down to ambient temperature was measured.

In this case, the electrocaloric material was not subjected to a varying electric

eld.

In the second case scenario, the sandwich-like structure was again heated up and

after it had reached the desired temperature of 85

lm heater was turned

off. However, this time, after the heater was turned off, the electrocaloric material

was subjected to a rectangular electric signal (thereby inducing the electrocaloric

°

C, the thin-

Search WWH ::

Custom Search