Environmental Engineering Reference

In-Depth Information

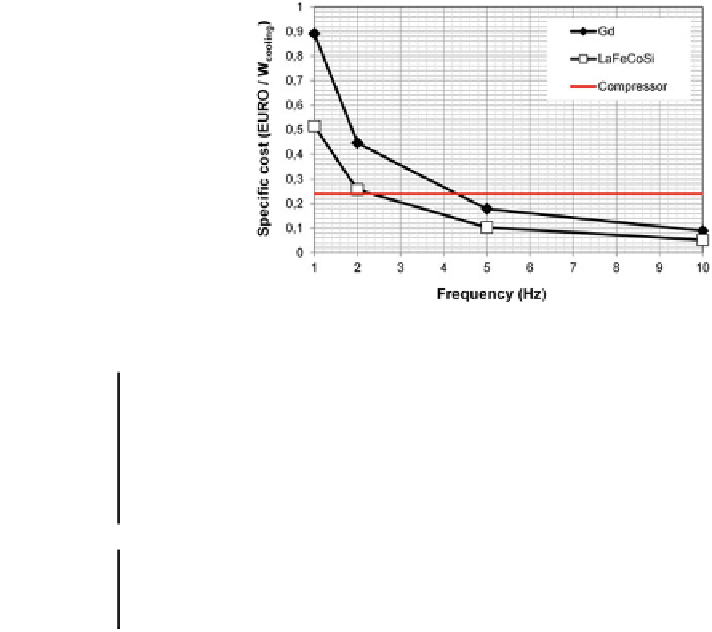

Fig. 9.3 Comparison of the

speci

c costs for a 50-W

c

compressor and the equivalent

ideal magnetic refrigerator

Table 9.4 The mass-production cost estimation of the magnet assembly in Fig.

9.3

Material

Eurokg

−

1

Mass

(kg)

COST

(Euro)

Manufacturing cost of

assembly

Total cost

(Euro)

NdFeB

40

6

240

+25 %

300

Soft iron

5

22.2

111

+25 %

139

AMR

LaFeCoSi

60

0.60

36

/

36

475

NdFeB

40

6

240

+25 %

300

Soft iron

5

22.2

111

+25 %

139

AMR Gd

150

0.66

99

/

99

538

comparison with the whole magnetocaloric device, a frequency of operation of

above 3 Hz will actually be required. At this frequency, the magnetic refrigerator

will have to operate with an ef

ciency at least as high as a compressor refrigerator,

as well as with an equivalent temperature span between the heat source and heat

sink (i.e. 40 K or more). Note again that the 40 K temperature span with the

predicted same or higher ef

ciency of the magnetic refrigerator represents an ideal

case. This also holds true for the frequency of operation. For such an ideal case the

AMR should actually consist of a layered magnetocaloric material and produced as

a structure with very tiny plates (a honeycomb or similar ordered structure) with

thickness of, e.g. 30

100

ʼ

, porosity of about 30

45 %, and with a similar thickness

-

-

of equally sized

fl

uid voids. For frequencies above 5 Hz, using water as the heat

transfer

uid in such an AMR will also not be a good option.

Note also that any complication related to the magnet structure will increase the

costs. In Fig.

9.2

, the magnet assembly applies simple rectangular prisms of per-

manent magnets. If we wish to make such magnets more complex, the

fl

rst question

is of course why is this required? For instance, we have already shown in the

eld is perhaps

Search WWH ::

Custom Search