Environmental Engineering Reference

In-Depth Information

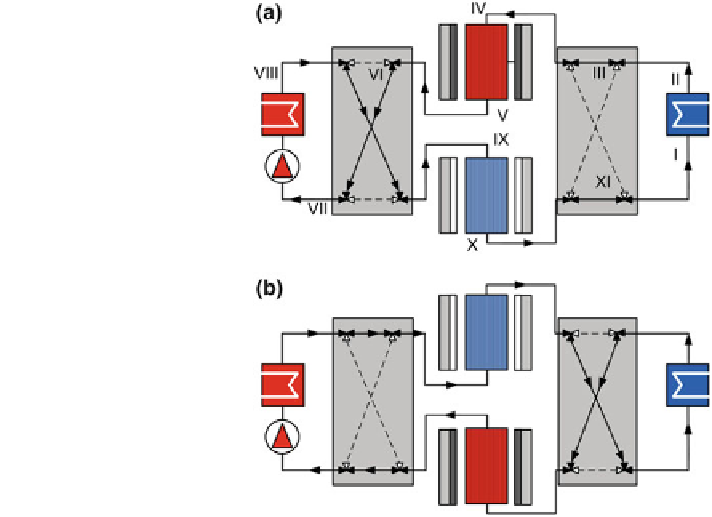

Fig. 8.17 A magnetocaloric

device with a rotary

movement of the magnet

assembly over two static

AMRs with the application of

the switching valve system

and the uni-directional pump

(a upper AMR magnetized,

lower AMR demagnetized; b

upper AMR demagnetized,

lower AMR magnetized),

classication no: R20(3)1(5)

(6)01101(12)

(stator) and the rotary part (rotor) (Fig.

8.18

b). The simplest case for the latter is to

apply a double or triple Halbach structure. However, this will not be the most cost-

effective solution. A more effective solution can be provided by the rotation of the

magnetic

eld source, such as, for example, shown in Fig.

8.19

.

According to Fig.

8.19

(left), a four-pole rotating magnet provides for the

magnetization and demagnetization of eight AMR beds. Such a magnet assembly

can be simply designed to be longer in the case of axial

ow (parallel to the

rotation axis), when a longer AMR is required. This certainly represents a simpler

construction over applications with a radial or azimuth

fl

uid

fl

ow through the AMR.

This is especially so if the up-scaling of devices is required. In Fig.

8.19

(right)

another example is shown in which the two-pole magnet is applied. In this case we

show two different examples of the magnetization of AMRs. However, in most

cases such an arrangement will provide a smaller magnetic

fl

uid

fl

fl

ux density than in the

case of Fig.

8.19

(left).

Another very important issue that needs to be addressed in the case of rotating

magnetic

eld sources is to follow the design and knowledge from permanent

magnet motors. Such an example is shown in the two cases of Fig.

8.20

.

In the cases a

c for Fig.

8.20

, we can follow the knowledge on the design of

permanent magnet motors in order to provide an ef

-

cient solution for the magnetic

fl

ux density in

such a particular case of multiple pole magnets will be, in most cases, low.

Therefore, compared to permanent magnet motors, the design architecture should

be modi

ux distribution as well as to minimize the torque. The magnetic

fl

ed for application of magnetic refrigeration.

Search WWH ::

Custom Search