Environmental Engineering Reference

In-Depth Information

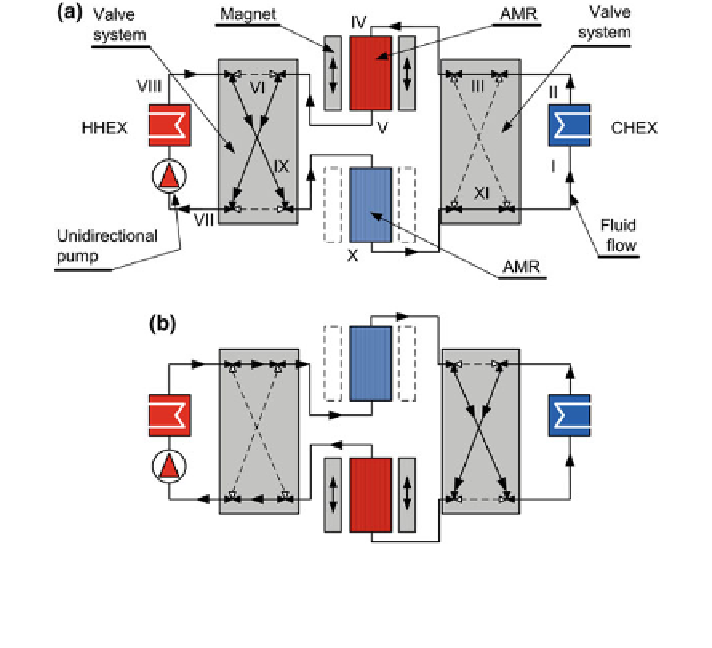

Fig. 8.3 A magnetocaloric device with a linear movement of the magnet assembly over two static

AMRs with the application of the switching-valve system and the uni-directional pump (a upper

AMR magnetized,

lower AMR demagnetized; b upper AMR demagnetized,

lower AMR

magnetized), classi

cation no: R20(3)1(5)(6)011001

II. From II it enters the switching-valve system III, which guides the fluid to the

AMR, which is in the magnetized state IV. There the

uid absorbs heat from the

AMR V and passes to the second valve system VI, where it is redirected to the

pump VII and HHEX. In HHEX it rejects heat to the environment VIII.

Then the

fl

fl

uid again enters the switching-valve system IX, which guides the

fl

uid

to another AMR, which is in the demagnetized state. The

uid cools down X and

enters the valve system XI. When the magnets move from the position in Fig.

8.3

a

to the position in Fig.

8.3

b, the valve system switches the directions of the

fl

fl

uid

fl

ow and thus provides a quasi-continuous production of cold. We denote it as

“

because of the fact that during the movements of the magnets, especially if

the AMR Brayton-like process is applied, this will require a certain time period.

If the magnetocaloric material moves instead of the magnetic

quasi

”

eld source

(Fig.

8.4

), this can be provided either with a static permanent magnet assembly or

with an electric coil. In the latter case, it of course makes sense to avoid any motion

(with

rst magnetic

refrigerators based on superconducting solenoids applied the motion of the mag-

netocaloric material in and out of the superconducting solenoid.

“

on-off

”

operation of the electromagnet). Note that

the

Search WWH ::

Custom Search