Environmental Engineering Reference

In-Depth Information

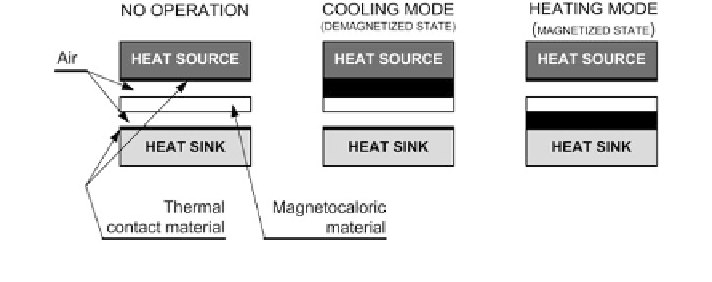

Fig. 6.9 Example of a thermal switch based on a mechanical contact

mechanical thermal switch serves for the thermal contact between the heat source

and the heat sink. The mechanisms behind these kinds of switches are based on

thermal actuation (the temperature-dependent elongation of materials), as well as

other types of actuation (electric, magnetic, chemical, etc.). Figure

6.9

shows an

example of a thermal switch based on a mechanical contact.

According to Fig.

6.9

there is a gap between the heat source and the heat sink. In

our particular case we will consider that air is used to

ll this gap. In the cooling

mode, when the magnetocaloric material is in the demagnetized state, the thermal

contact material (thermal switch) is active, which means that it is elongated and in

such a way that it is in contact with the heat source. The heat is transferred through

the thermal switch by thermal diffusion (conduction). In the heating mode, the

lower thermal switch is active and the upper thermal switch is inactive. Now the

heat

ux can be transferred to the heat sink.

The thermally rectifying materials, which are based on thermally activated

elongation, must exhibit high thermal conductivity. Most of these mechanisms can

be referred to as passive and thermally actuated. This group of materials includes

elastomers (solid, liquid), bimetals, shape-memory alloys, etc.

Shape-memory metallic alloys exhibit thermomechanical actuation. One of the

most representative alloys is the nickel

fl

-

titanium alloy; however, there are a number

·

of other potential materials, e.g. Co

-

Ni

-

Al, Co

Ni

-

Ga, Fe

-

Mn

-

Si, Cu

-

Al

-

Ni,

Cu

Pt. In the group of non-metallic materials we should not neglect the

shape-memory polymers [

57

-

Zn and Fe

-

62

], which can be activated by many different

mechanisms, i.e. thermal, electrical, radiative (light), magnetic or chemical [

62

].

The selection of shape-memory materials generally depends on the mode of actu-

ation, the operating temperature and the desired behaviour.

Other types of materials can be referred to as bimetals. This kind of material is

made by bonding different metals in a bimetallic strip, e.g. steel and copper or steel

and brass, whereas each metal possesses a different coef

-

cient of thermal expan-

sion. The temperature gradient will lead to the mechanical displacement of such

material.

The major drawback of all contact thermal switch mechanisms, besides the

thermal contact resistance between the thermal switch and the magnetocaloric

Search WWH ::

Custom Search