Environmental Engineering Reference

In-Depth Information

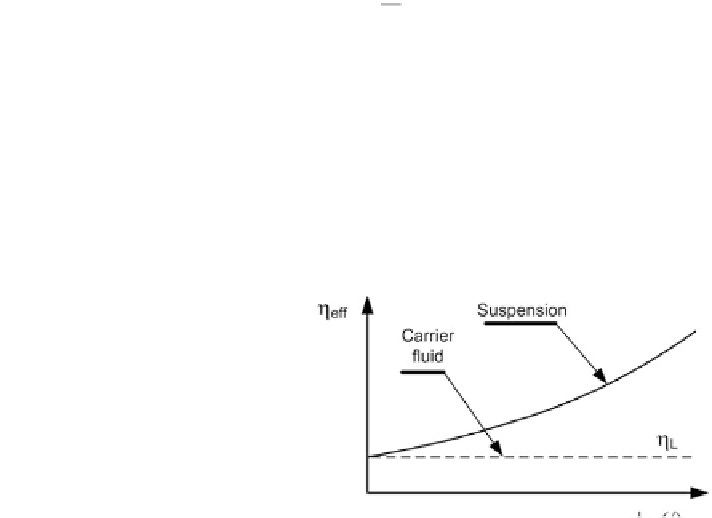

5.1 Rheology of Suspensions

Fluids can be divided according to their rheological behaviour into Newtonian and

non-Newtonian

fl

uids. Newtonian

fl

uids follow Newton

'

s law of viscosity, which is

expressed in one-dimensional form as

dv

dy

s

¼

g

L

ð

5

:

1

Þ

It is clear from Eq. (

5.1

) that the relation between the velocity gradient (shear

rate) and the shear stress in a Newtonian

fl

uid is linear. In order to account for the

solids content in a carrier or base

fl

uid, Einstein [

1

,

2

] derived an equation for the

“

”

viscosity of a homogeneous Newtonian suspension, comprising spher-

ical particles with a small volume concentration:

effective

g

eff

¼

g

L

1

ð

þ

2

:

5

/

V

Þ

ð

5

:

2

Þ

ϕ

V

is the volume fraction of the solid phase in a solid-liquid

suspension. Note that Eq. (

5.2

) does not take the sizes or positions of the particles

into account, and the theory neglects the effects of particle interaction. The shear

stress in this case is expressed by replacing the liquid-phase viscosity

In this equation,

ʷ

L

with the

effective viscosity

ʷ

eff

.

dv

dy

s

¼

g

eff

ð

5

:

3

Þ

After Einstein [

1

,

2

], several models for effective viscosity were proposed. They

comprise additional terms to describe the interaction between particles, account for

high concentration of solid particles, their size and their shape. Figure

5.1

shows the

difference in dynamic viscosity between the carrier

uid and effective viscosity of a

Newtonian suspension. Because of the complexity of a theoretical description, these

models are based on empirical evaluation.

The rheological behaviour of a homogeneous, non-Newtonian

fl

fl

uid in the case

of highly turbulent

fl

ow or in the case of small concentrations of a solid phase

Fig. 5.1 An example of the

variation of the effective

viscosity with the

concentration of solids

Search WWH ::

Custom Search