Environmental Engineering Reference

In-Depth Information

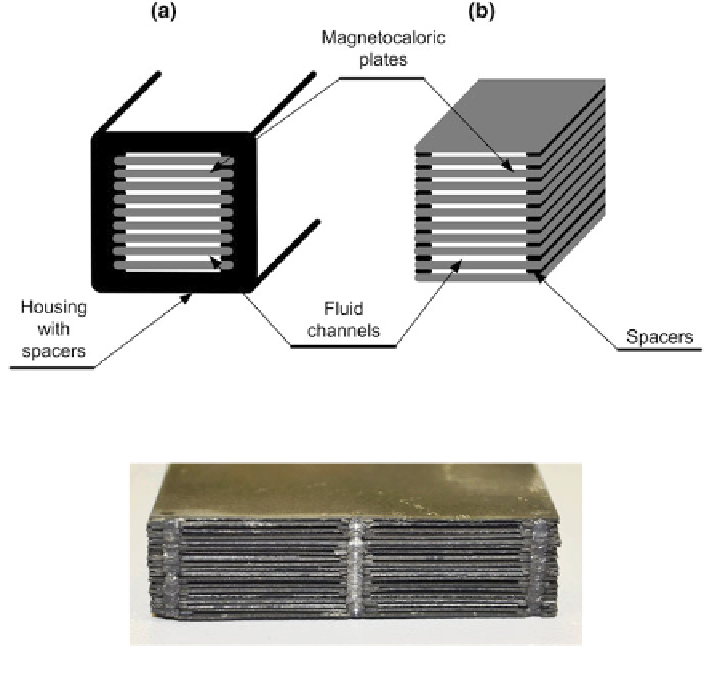

Fig. 4.35 a

AMR with spacers integrated into the housing.

b

Jointed AMR

Fig. 4.36

A photograph of a laser-welded AMR with a plate thickness of 0.25 mm

spacings can be joined by gluing [

132

] or laser welding [

101

]

see Fig.

4.36

. The

laser welding of the AMR is especially interesting since it enables a precise and

permanent joint of an arbitrary thin spacer and the magnetocaloric plate, and is

further insensitive to the working

—

uid. The spacer must, of course, be weldable,

with the magnetocaloric material used (for example gadolinium and stainless steel

as a spacer are compatible).

fl

4.7.2 Fabrication of Powder-Based (sintered) AMRs

The magnetocaloric materials produced by powder metallurgy, e.g. La-based and

Mn-based materials, require special forming and processing techniques for the

AMR

s fabrication [

133

]. The great majority of these types of materials were tested in

the form of a powder in packed-bed AMRs [

5

]. However, some fabrication methods

for producing powder-based ordered AMRs were presented and evaluated as well.

'

Search WWH ::

Custom Search