Environmental Engineering Reference

In-Depth Information

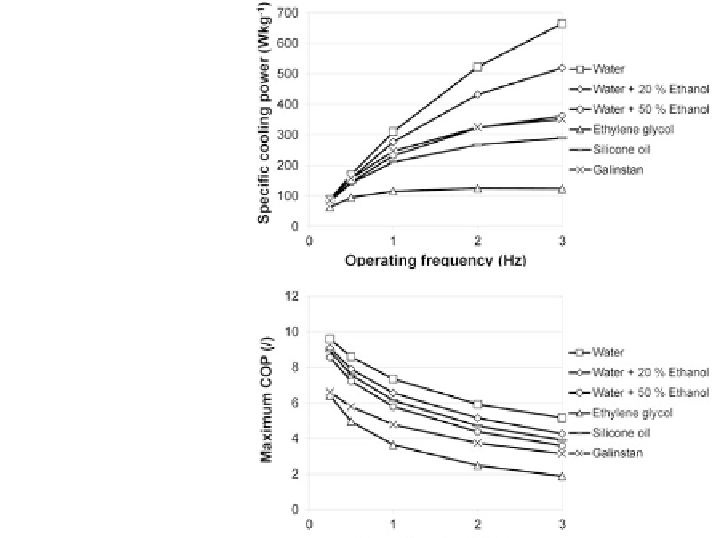

c cooling power (per mass of

magnetocaloric material) and the maximum COP (obtained at the optimum utili-

zation factor

Figures

4.32

and

4.33

show the maximum speci

uids as a

function of the operating frequency for packed-bed and parallel-plate AMRs,

respectively. The temperature span between the heat source (293 K) and the heat

sink was set at 15 K.

The trend of dependency for the speci

—

mass

fl

ow rate for each case) for all the analysed working

fl

c cooling power and the COP with the

operating frequency presented in Figs.

4.32

and

4.33

is in general expected and

explained in more detail in Sects.

4.4

and

4.5

(for water as a heat-transfer

uid).

It was also expected that due to the better heat transfer geometry the packed-bed

compared to parallel-plate AMR would have a higher speci

fl

c cooling power and a

higher optimum operating frequency (the exception here is Galinstan in the parallel-

plate AMR, as explained below), but also smaller COP values due to higher viscous

losses.

In the case of the packed-bed AMR the best cooling characteristics were

obtained with water. The additives of ethanol signi

cantly reduce the performance

of a device, especially the cooling power at frequencies above 1 Hz (mostly due to

the lower thermal diffusivity and thermal conductivity). Even though Galinstan has

by far the highest thermal diffusivity of all the evaluated

uids, it does not perform

as well as some might expect in the packed-bed AMR. This is mostly due to its very

high density and the viscous losses, which prevent a better performance. A similar

situation is also true for ethylene glycol, which suffers from a very high viscosity

fl

Fig. 4.32

The maximum

speci

c cooling power and

the maximum COP for the

analysed working

uids as a

function of the operating

frequency for a packed-bed

AMR at 1 T of magnetic

eld

change and 15 K of

temperature span

fl

Search WWH ::

Custom Search