Environmental Engineering Reference

In-Depth Information

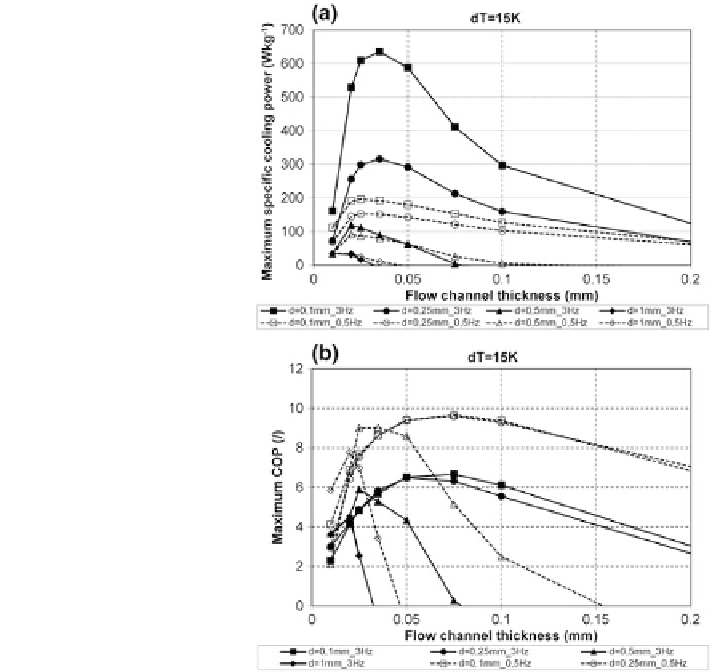

Fig. 4.21 a

The maximum

speci

c cooling power as a

function of the channel

thickness for the parallel-plate

AMR at two different

operating frequencies (dotted

lines for 0.5 Hz and full lines

for 3 Hz) and four plate

thicknesses.

b

The maximum

COP as a function of the

channel thickness for the

parallel-plate AMR at two

different operating

frequencies (dotted lines for

0.5 Hz and full lines for 3 Hz)

and four plate thicknesses

However, even though it is to be expected that different magnetocaloric mate-

rials, different heat-transfer

eld changes, etc. would

probably lead to different optimum AMR geometries, as shown below, it is crucial

to be aware of the impact of the thermohydraulic properties and the AMR geometry

on its cooling characteristics.

Figure

4.15

shows the speci

fl

uids, different magnetic

c cooling power and the COP as a function of the

sphere diameter for different lengths of a packed-bed AMR. It is evident that there

is a well-dened optimum sphere diameter for each length of the packed-bed AMR

from the point of view of the speci

c cooling power as well as the COP. In the case

of a small sphere diameter (below the optimum value), the viscous losses dominate

and are increasing with a decreasing sphere diameter and an increased length of the

AMR. In the case of a greater sphere diameter (above the optimum value) the heat

transfer losses dominate, since in this case the AMR is

lled with larger spheres,

which leads to a smaller heat transfer coef

cient and a smaller total heat transfer

area. It is further evident that at a high operating frequency, the packed-bed AMR

shows the best performance for very short lengths (20 mm or even less, according

to the presented trend of dependency), while at a low operating frequency the best

Search WWH ::

Custom Search