Environmental Engineering Reference

In-Depth Information

thermodynamic cycle (hence the name active). It is therefore more compact than a

system with a separated passive regenerator as well as being more ef

cient. The latter

is mostly due to the smaller heat transfer losses, which in the case of a passive

regenerator occur during the heat transfer between the regenerative and the mag-

netocaloric materials (directly or through the external

ow) [

8

]. As discussed

later in this chapter, the AMR performs its own unique thermodynamic cycle, while

the passive regenerator performs only a particular process of the thermodynamic

cycle. Note the passive regenerative material is not a thermodynamically working

substance like the magnetocaloric material is in the AMR.

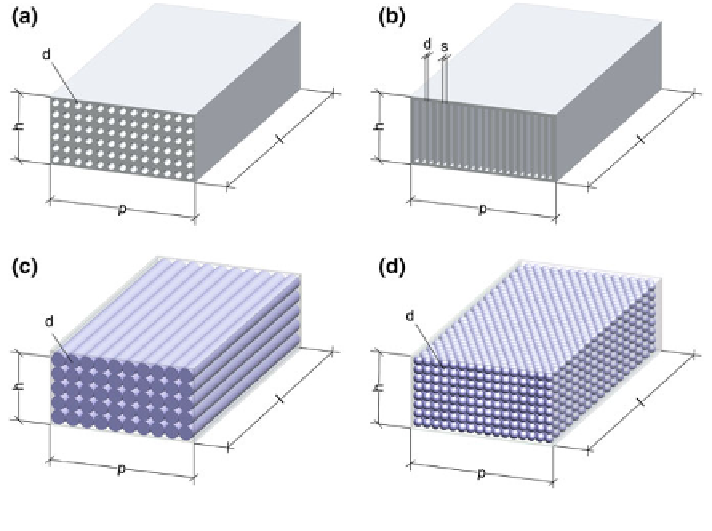

Figure

4.1

shows schematics of four different AMRs in different geometrical

forms (perforated-plates AMR (a); parallel-plate AMR (b); wires-like AMR (c) and

packed-bed AMR (d)). The parallel-plate and packed-bed AMRs are the most

widely applied to date [

5

].

In this chapter, the principle of the AMR operation is explained and discussed.

Different thermodynamic cycles with the AMR and its characteristics are shown

and the layered-bed AMR principle is introduced. Furthermore, numerical model-

ling of the AMR is described. Theoretical (numerical) as well as some experimental

results of the AMR operation are shown. These are based on simulations and

optimization of different operating conditions (utilization factor and operating fre-

quency), different geometries of packed-bed and parallel-plate AMRs, different

AMR thermodynamic cycles and application of different heat-transfer fluids. At the

fl

uid

fl

Fig. 4.1

Schematic example of four different AMR geometries

Search WWH ::

Custom Search