Environmental Engineering Reference

In-Depth Information

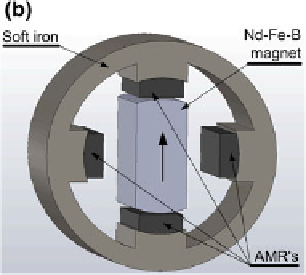

Fig. 3.39 The magnet assembly with the four rounded iron poles and four rounded AMRs and

with the rotating bar magnet (see also Bouchekara et al. [

56

])

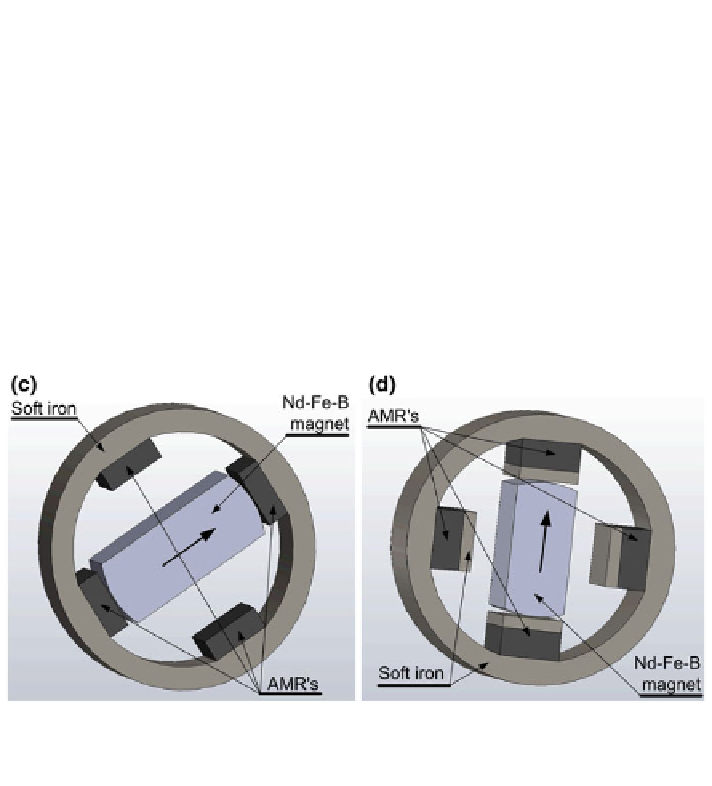

Fig. 3.40 The magnet assembly without iron poles, c the four rectangular AMRs are attached to

the smooth static iron ring, d the four rectangular AMRs are attached to the smooth static iron ring

and 10 mm steel is attached to AMRs (see also Bouchekara et al. [

56

])

of 10 mm were attached to the AMR beds. The idea here was to bring support that

would sustain tangential forces instead of the AMRs.

The magnet assemblies (e) and (f) in Fig.

3.41

comprise six poles each. The idea

behind the increased number of poles was that a larger number of poles reduce the

magnetic torque of the system. Therefore, the magnet assembly (e) had the same

shape as the reference magnet assembly (a); however, it comprised six poles of soft

iron to which six AMRs were attached. The design of the magnet assembly denoted

by (f) is similar. This magnet assembly did not comprise iron poles, similar to the

magnet assembly (c) (in the Fig.

3.40

); however, it comprised six beds of AMRs.

An additional change was made in the magnet assembly denoted by (g)

(Fig.

3.42

). This magnet assembly was similar to the magnet assembly (f) (from

Fig.

3.41

); however, with the difference being that the AMRs were embodied into

the smooth iron ring, thus having no iron poles.

Search WWH ::

Custom Search