Biomedical Engineering Reference

In-Depth Information

25

20

15

10

5

0

0

200

400

600

800

1000

Time (s)

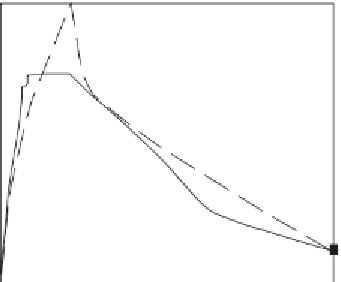

Figure 7.11

Binding of 6 mM glucose to an implantable glucose sensor (Vaddiraju et al., 2008).

coefficient increases by a factor of 28.6 from a value of

k

1

equal to 0.6473 to

k

2

equal to 18.5.

Similarly, for the dissociation phase, as the fractal dimension increases by a factor of 2.48

from a value of

D

fd1

equal to 0.898 to

D

fd2

equal to 2.2282, the dissociation rate coefficient

increases by a factor of 57.87 from a value of

k

d1

equal to 0.0207 to

k

d2

equal to 1.1878. In

both the cases mentioned above, an increase in the degree of heterogeneity on the biosensor

surface (increase in the fractal dimension) leads to a corresponding increase in the rate

coefficient.

Recently,

Pemberton et al. (2009)

have fabricated a microband glucose biosensor using a

screen-printed WB carbon ink and used it for serum analysis. They used this sensor for glu-

cose analysis at 25

C. They optimized the operational pH at 8.0. Steady-state conditions

were determined indicating the presence of radial diffusion.

Pemberton et al.

(

2009

) report that the screen-printing approach has been used for biosensor

fabrication on an industrial mass production scale (

Newman and Setford, 2006

). It is partic-

ularly suitable for the production of low cost disposable devices. They further point out that

they have been successfully employed to make the test strips used by diabetics to monitor

their blood glucose levels (

Matthews et al., 1987

).

Pemberton et al. (2009)

point out that to demonstrate microelectrode behavior using screen-

printing technology with carbon inks, a working electrode of micron size in at least one

dimension is required. Their sensor, fabricated using a solvent-based CoPC-containing

carbon ink, demonstrated microelectrode-type behavior. Their sensor was capable of

exhibiting steady-state current responses in the presence of H

2

O

2

(

Rawson et al., 2007

).