Biomedical Engineering Reference

In-Depth Information

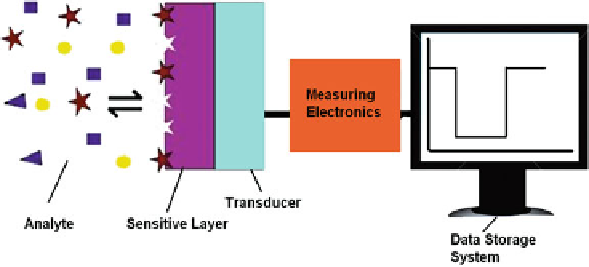

Fig. 5 General diagram of chemical sensor

technological methods. A general schematic diagram of a chemical sensor is shown

in Fig.

5

.

Generally speaking, a chemical sensor consists of a recognition layer that is

sensitive to chemical changes taking place in the surrounding environment. Upon

interaction with the target analyte, a change takes place in one of the physical

properties of the layer. The transducer detects this change and converts it into a

useful analytical signal and thus quantifiable data. The resulting electronic signals

are usually amplified and recorded by a data processing unit, often including

evaluation. Sensor layers play a crucial role in the efficiency of a chemical sensor,

because they partly determine sensitivity and are mainly responsible for selectivity,

response time, and lifetime of a chemical sensor. On the transducer side, a wide

range of physical parameters can be exploited for generating the sensor signal.

Hence, the most common chemical sensors can be classified into electrochemical,

optical, piezoelectric, and semiconductor sensors.

Electrochemical sensors measure a change in, e.g., voltage ocurring at the

selective layer on analyte exposure against a reference or also amperometric and

voltammetric signals. One of the first MIP-based amperometric sensors was devel-

oped by Piletsky et al. [

23

] to determine aniline and phenol. Similarly, Vinokurov

reported an early potentiometric MIP sensor [

24

] based on the electropoly-

merization of pyrrole, amines, and substituted phenols. In contrast to these, piezo-

electric devices detect mass of an analyte and convert

it

to an electrically

measurable quantity, usually a change in frequency.

The most commonly used piezoelectric material in mass-sensitive chemical

sensing is AT-cut quartz with circular electrodes patterned on both sides leading

to so-called QCM in which thickness shear waves are generated by applying

electric potential between the electrodes. Figure

6

shows a typical example of

such a device with dual-electrode geometry to ensure compensation of interferences

caused, e.g., by changing temperature or viscosity. QCM are useful for achieving a

broad range of sensitivity: for example Cabanilla et al. introduced a piezoelectric

sensor for the detection of caffeine, reaching a dynamic range from 0.1 to

10 mg mL

1

[

25

]. The sensitivity of piezoelectric sensors is often somewhat

lower by comparison with optical and electrochemical sensors; however, it can be

Search WWH ::

Custom Search