Biomedical Engineering Reference

In-Depth Information

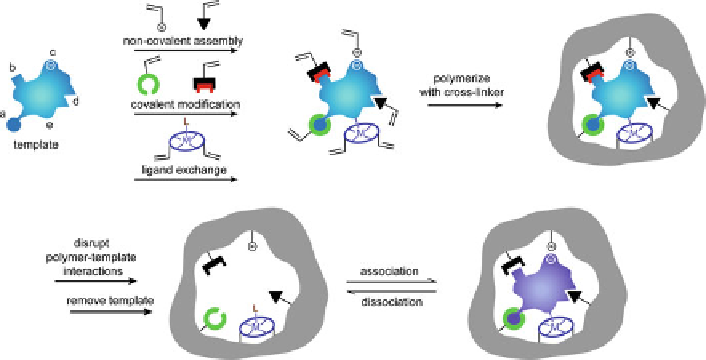

Fig. 1 Schematic representation of molecular imprinting. Template and the polymerizable func-

tional monomer may interact through: (a) reversible covalent bonds, (b) covalently attached

polymerizable binding groups that are activated for non-covalent interaction by template cleavage,

(c) electrostatic interactions, (d) hydrophobic or van der Waals interactions, (e) metal-ion

mediated interactions (adapted with permission from [

30

])

non-covalent interactions. The reaction mixture includes a cross-linker and a

porogenic solvent. Polymerization is initiated either thermally or by UV light,

leading to highly cross-linked polymers. The template is removed from the polymer

by washing, leaving behind binding sites that are both spatially and chemically

complementary to the template molecules, and capable of rebinding either the

template or its structural analogues [

29

,

30

].

In contrast to biomolecules, MIPs are usually stable at low and high pH,

pressures and temperatures (

150

C) [

15

,

31

-

36

]. Moreover, they are less expen-

sive than biomolecules and easier to obtain, and they can be used in organic

solvents. Finally, they can be synthesized for diverse classes of substances, such

as ions [

37

], nucleic acids [

38

], proteins [

39

,

40

], drugs [

41

-

43

], and even yeast

cells and erythrocytes [

44

].

The number of published papers in the MIP area in the last 10 years has tripled,

which reflects the growing interest in these materials [

45

]. However, MIPs are also

burdened with some limitations, mainly connected with the methods of their

production and the final format of the polymer. One such limitation is linked to

MIPs prepared in the “bulk” format, which require grinding and sieving to obtain a

fraction of particles with a narrow range of sizes. This is a lengthy process and is

impractical or unsuitable for many applications [

46

-

48

]. Furthermore free radical

addition polymerization is exothermic and the bulk format prevents efficient heat

exchange with the exterior. This can lead to rapid increases in the temperature of the

polymerization mixture and consequently increased pressure within the reaction

mixture, which may adversely affect MIP properties and can lead to explosions for

<

Search WWH ::

Custom Search