Biomedical Engineering Reference

In-Depth Information

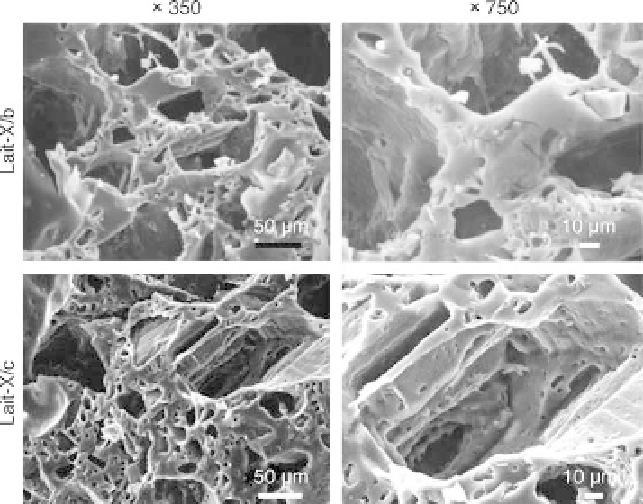

17.5 SEM images of cross-linked PLA porous scaffolds: Lait-X/b and

Lait-X/c, for 350

magnifications. Reprinted with permission

from Wiley-VCH (Sakai et al., 2012).

6

and 750

6

confirming biocompatibility through the cell-scaffold interaction. The in-

vitro degradation of the PLA thermoset scaffolds in a phosphate-buffered

solution was faster for samples prepared by foaming and subsequent

leaching (Sakai et al., 2012). The agglomeration of the smaller crystal (solid

porogen) within the 3D polymer matrix enables the creation of an

interconnected pore network with well-defined pore sizes and shapes.

17.4.2 Thermally-induced phase separation (TIPS)

Three-dimensional

(3D) resorbable polymer scaffolds with very high

porosities (

97%) can be produced using the TIPS technique to give

controlled microstructures that form scaffolds for tissues such as nerve,

muscle, tendon, intestine, bone and teeth (Boccaccini and Maquet, 2003).

The obtained scaffolds are highly porous with an anisotropic tubular

morphology and extensive pore interconnectivity. The microporosity of

TIPS-produced foams, their pore morphology, mechanical properties,

bioactivity and degradation rates can be controlled by varying the polymer

concentration in solution, the volume fraction of the secondary phase,

quenching temperature and the polymer and solvent used (Boccaccini and

Maquet, 2003).

When dioxane alone was used, the porous structure resulted from a solid-

liquid phase separation of the polymer solution. During quenching, the

~