Biomedical Engineering Reference

In-Depth Information

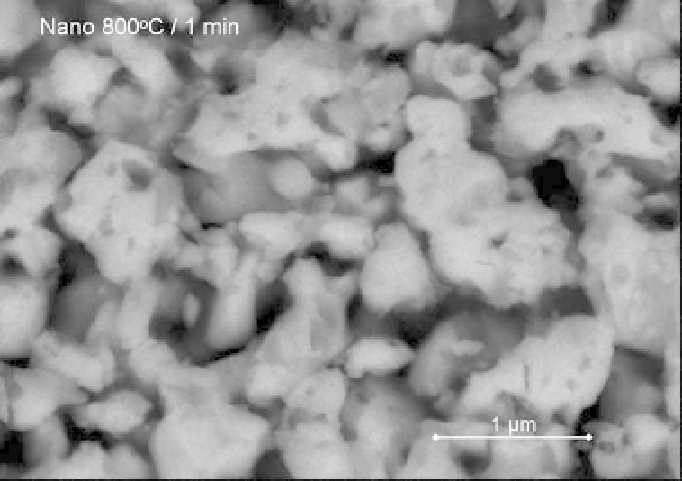

13.21

Densification and grain growth within individual aggregated

particles prior to bulk densification.

In liquid-phase sintering systems, it is believed that the solution-

reprecipitation mechanism may also help facilitate the coalescence of grains.

Direct evidence of coalescence is, however, very difficult to identify. Fang

et al.

79

studied the grain growth of nano WC during sintering and found the

growth of nanosized tungsten carbide grains within aggregates via

coalescence, as shown in Fig. 13.20. An analysis of the sintering of WC-

Co composites suggests that the lattice shift along low-energy CSL grain

boundaries is a viable mechanism for materials with a high degree of

crystallographic anisotropy.

106

Effects of agglomerates on initial grain growth

Another important factor in grain growth mechanisms during sintering of

nano particles is the role of agglomerates in grain growth. Agglomerates are

defined as loosely-packed particles forming fractals, while aggregates are

particles packed together in a more defined equiaxial shape. Mayo

3

pointed

out that grain size is often related to the size of agglomerates at the

beginning of sintering. As Mayo summarized, the larger the agglomerate

size, the higher the sintering temperature required to eliminate large inter-

agglomerate pores. By contrast, the crystallite size has little effect on the

temperature required to reach full density. The same temperatures, however,

promote grain growth to such an extent that the grain size can easily balloon

to the agglomerate size.

Fang

107

observed a similar phenomenon. Figure 13.21 shows an