Biomedical Engineering Reference

In-Depth Information

13.18

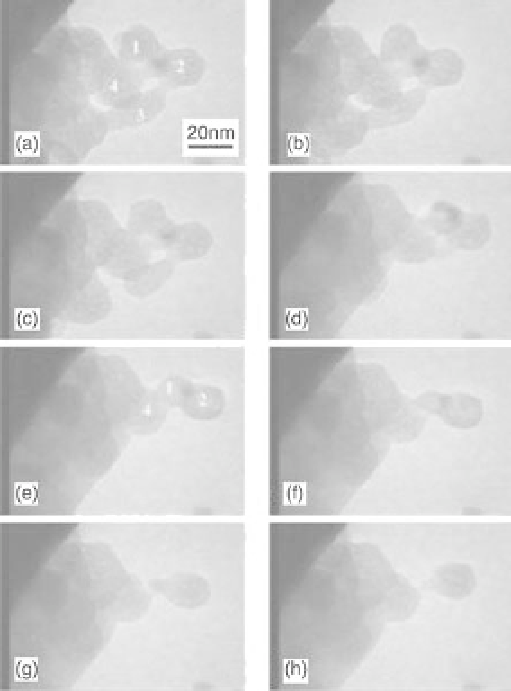

Observations of the grain growth in BaTiO

3

powder at different

temperatures from 940

C (d to o). Grains

grow through reduction of smaller grains and enlargement of larger

ones. The distance between the particle centers decreases

simultaneously.

8

C (a), 950

8

C (b, c) to 960

8

Considering that nano particles are usually not at equilibrium states and

are likely to contain excess amounts of various defects that are created

during the production of nano particles, there will be a relaxation period for

migration, redistribution and annihilation of the defects.

96,97

Owing to the

non-equilibrium structure of nano particles, diffusivity is dramatically

enhanced during the relaxation process,

98-101

which may contribute to

dynamic grain growth at the beginning of sintering. Dynamic grain growth

usually dominates during the heat-up stage and for the first few minutes

after reaching a preset isothermal holding temperature. Therefore, rapid

dynamic grain growth accounts for the experimental observation that the

first data point during isothermal holding is several times that of the initial

grain size. The relaxation time depends on materials, nano particle

production methods and temperature.

The role of grain boundary migration should also be considered in