Biomedical Engineering Reference

In-Depth Information

13.14

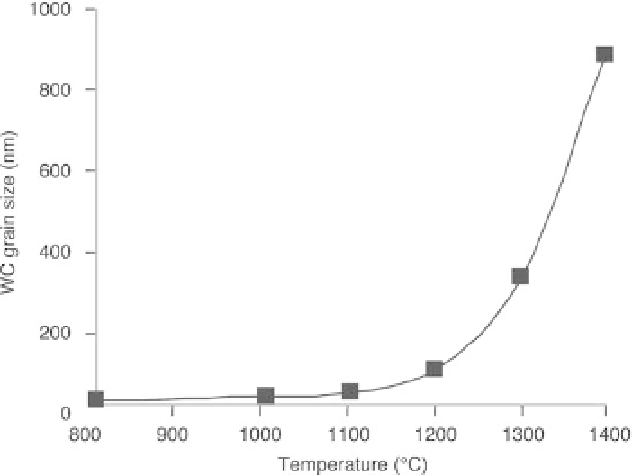

Grain size vs. temperature during heating up of nanocrystalline

WC-Co powder at a heating rate of 108C/min.

Grain growth during sintering of nano particles is also a strong function

of temperature. Figure 13.13

78

shows the relationship between grain size and

temperature during the heat treatment of nanocrystalline cobalt powder. It

is obvious that the grain growth is initially slow at very low temperatures

and that it accelerates dramatically when the temperature is above an

apparent critical temperature range. Figure 13.14 provides another example

of the relationship between grain size and temperature during heating up of

nanocrystalline WC-Co powder at a heating rate of 10

C/min.

79

It shows

that the original 20 nm grain size has increased almost 45-fold to 900 nm.

This 'explosive' grain growth occurs almost instantly during heat-up, with

no significant holding time. Similar behavior has also been reported for

sintering of other nanocrystalline ceramics, as well as for metallic

powders.

80-86

It appears that a critical temperature exists, above which

the grain growth accelerates dramatically as a function of temperature.

The issue of grain growth during sintering can be studied by examining

the grain size versus relative density relationship. This approach has been

applied to the study of sintering of nano particles. A typical relationship

between grain size and density during sintering of nano particles is

schematically shown in Fig. 13.15. In one of the earliest studies of the

sintering and grain growth of nanosized ceramic powders in the 1990s,

Owen and Chokshi

87

and Averback et al.

88

showed that oxides densify

without significant grain growth until the density reaches approximately

90% of the bulk density. Then the grain growth becomes very rapid. This

8