Biomedical Engineering Reference

In-Depth Information

9.4

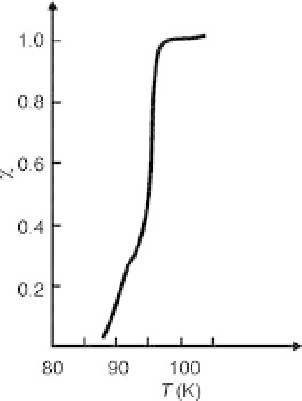

Curve of SC transition for composite obtained during

polymerization of MMA in pressed samples of the Y

1

Ba

2

Cu

3

O

7

x

ceramic at 80

8

C. Ceramic:binder weight ratio is 88:12 [21].

SC characteristics shows that, in all samples, the Meissner effect was

observed without a restoration stage. The character of transition to the SC

state for composites with MMA binder, obtained through polymerization

filling, is given in Fig. 9.4.

Unexpected results were obtained while studying the influence of the

Y

1

Ba

2

Cu

3

O

7

x

oxide ceramic on the kinetics of MMA polymerization in the

presence and absence of the initiator AIBN. The results revealed that for

long periods (around 4-5 hours) no polymerization takes place. However, in

the absence of an initiator, polymerization occurs quite quickly when the

filling rate was higher (Y

1

Ba

2

Cu

3

O

7

x

MMA+AIBN=90:10; 85:15, % by

weight). For elucidation of such anomalies, the influence of various

quantities of Y

1

Ba

2

Cu

3

O

7

x

ceramic on the polymerization kinetics of

MMA, both in the presence and absence of AIBN, was specifically

investigated.

A series of kinetic curves showing this influence of Y

1

Ba

2

Cu

3

O

7

x

ceramic on the polymerization of MMA is presented in Fig. 9.5 and Fig.

9.6(a), for the presence and absence of the ceramic respectively. From

kinetic curve 1 (Fig. 9.5) it can be seen that in the absence of ceramic, the

kinetics of the initiated polymerization of MMA follows a conventional

trend. The maximum heat evolution is about 130 kcal/degree, which

corresponds to the heat effect of MMA polymerization. Addition of

Y

1

Ba

2

Cu

3

O

7

x

(Fig. 9.6, curves 2-5) decreases not only the rate of

polymerization, but the marginal rate of conversion as well.

This is in contrast to the effects observed when polymerization of MMA

is carried out in the absence of AIBN. In this case, as demonstrated by