Biomedical Engineering Reference

In-Depth Information

8.2

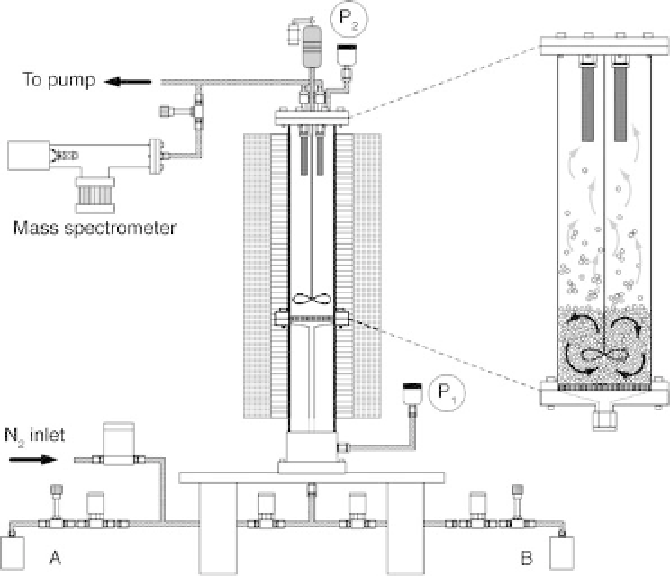

Schematic illustration of ALD fluidized bed reactor (King

et al

.,

2007). Reproduced by permission of Elsevier.

metal walls was positioned inside a vacuum chamber. The porous cylindrical

drum was rotated by a magnetically coupled rotary feedthrough.

The FBR has many advantages, including good mixing, large gas-solid

contact area, high efficiency of mass and heat transfer, and large-batch

processing capability. With appropriate expansion of a bed of particles,

granular materials are transformed into a fluid-like state through contact

with a gas or a liquid. The rigorous mixing during fluidization provides

excellent fluid-solid contacting. In an FBR system, gas precursors can be

introduced into the bed for reaction with the surface of the particles, while

the particles are circulating in a liquid-like state. Ultra-thin films can be

coated on primary nanoparticles without significant aggregation during the

ALD coating process. This phenomenon can be explained by a behavior

called dynamic aggregation (Hakim et al., 2005c), which is observed during

the fluidization of nanoparticles. The native cohesive properties of the

nanoparticles will form agglomerates that are several times larger than the

primary particles. Dynamic agglomerates partially break apart and reform

due to constant solids recirculation and gas flow through the bed of

particles. External forces, such as mechanical vibration, can improve

fluidization quality by helping to partially overcome interparticle forces.

This serves to reduce the average size and increase the disengagement rate of