Biomedical Engineering Reference

In-Depth Information

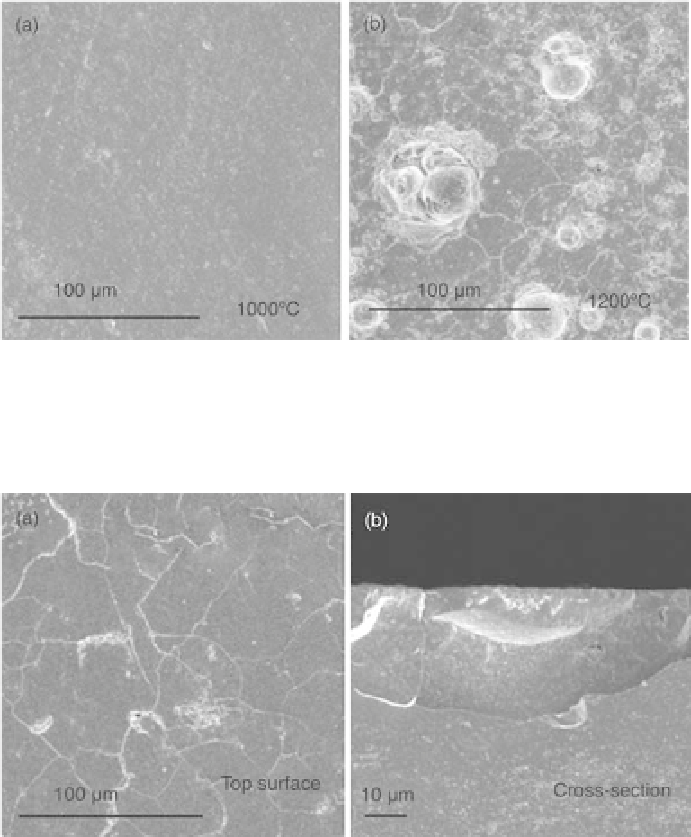

7.19

2.5wt% MWCNT-SiO

2

composites after thermal shock test from

(a) 1000

8

C and (b) 1200

8

C. No cracks can be seen in specimen quenched

from 1000

8

C while the specimen quenched from 1200

8

C showed cracks

due to the formation of cristobalite.

7.20

2.5wt% MWCNT-SiO

2

composites after thermal shock test

comprising 20 cycles from 1000

C. Cracks can be seen on (a) surface and

(b) cross-section of the specimen due to cristobalite formation because

of thermal cycling.

8

20 times, did not lead to failure of the composites due to thermal shock but

it encouraged devitrification in silica glass. Figure 7.20 shows images of the

surface and cross-section of CNT-SiO

2

composites thermally cycled up to

1000

C, 20 times; surface cracks only formed due to the crystallization of

cristobalite at 1000

8

C on repeated heating of the specimens. It can be

inferred from the results on CNT-SiO

2

composites that the incorporation of

CNTs is likely to increase thermal shock resistance when reinforced in glass

systems susceptible to thermal shock.

Thermal ageing of CNT-glass/glass-ceramic composites is another

important area of research in order to find the maximum working

8