Biomedical Engineering Reference

In-Depth Information

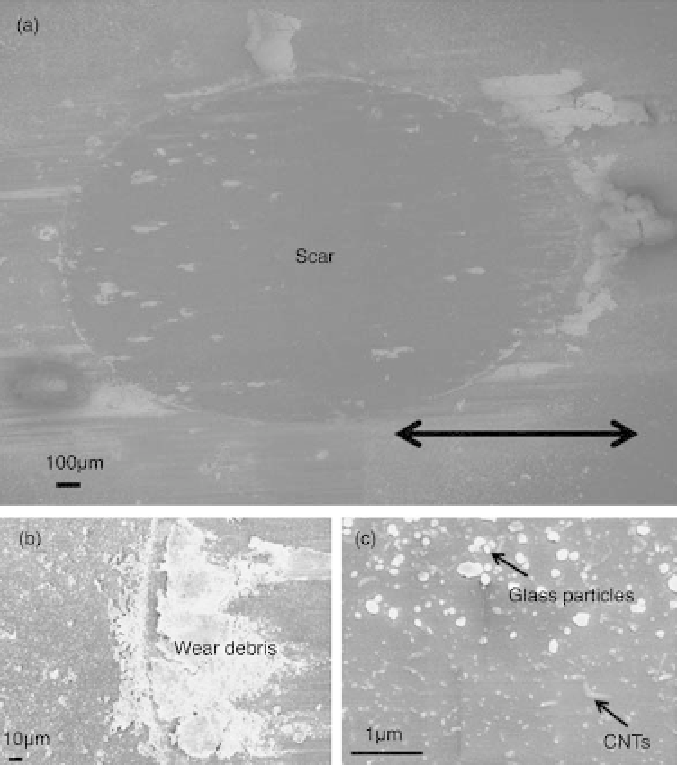

7.18 (a) Wear scar produced in 7.5wt% MWCNT-SiO

2

composite

specimen after test. (b) Wear debris containing glass particles is evident.

(c) Pulled out glass particles are also shown at the edge of the scar;

CNTs have been exposed on the scar surface.

to be more than that of the glass specimen. This result suggests that the

incorporation of CNTs in glasses/glass-ceramics decreases the friction

coefficient by acting as a solid lubricant between the contacting surface of

the sliding pin and the specimen. A possible reason for the unexpected

increase in wear volume may be the decrease in hardness of composites by

adding CNTs. Figure 7.18(a) shows a scar produced on the 7.5wt% CNT-

SiO

2

composite specimen after the wear test. Wear debris produced is shown

at the edge of the scar (Fig. 7.18(b)) along with the pulled out glass particles

(Fig. 7.18(c)). In the process, the reinforced CNTs have been exposed due to

the ploughing of composite surface by the sliding pin (Fig. 7.18(c)). A detailed

study is required to fully explore the wear and friction properties of CNT-

glass/glass-ceramic matrix composites and the wear mechanisms involved.