Biomedical Engineering Reference

In-Depth Information

7.17

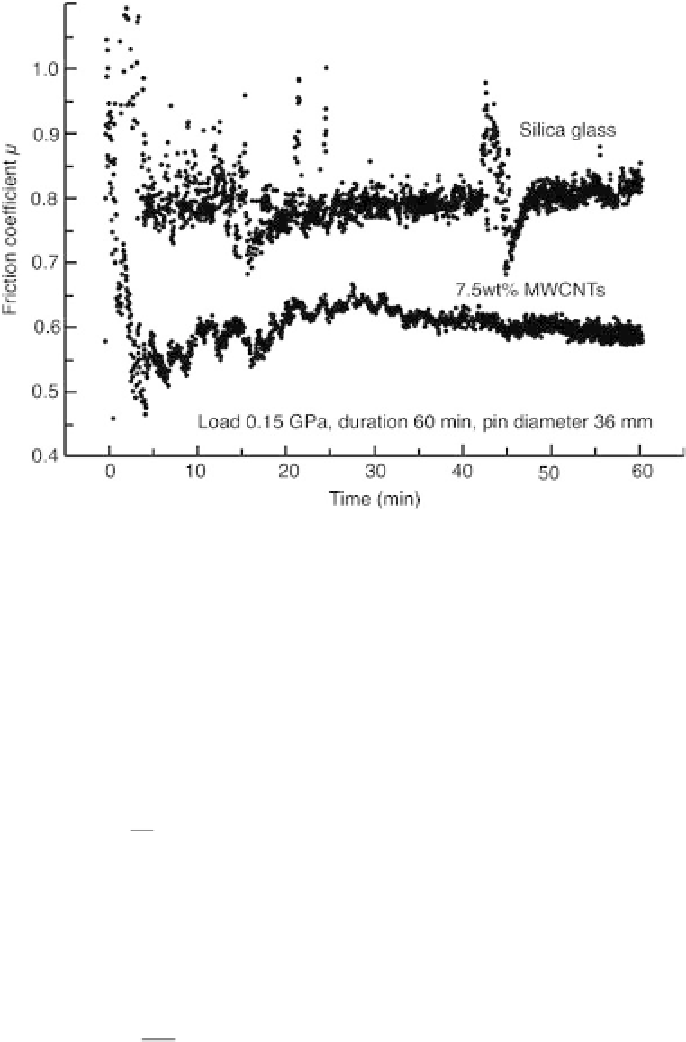

Friction coefficients of silica glass and 7.5wt% MWCNT-SiO

2

composite. A decrease in friction coefficient can be seen in the

composite (from 0.8 to 0.6).

used with varying applied loads and sliding speeds depending on the

composite specimens to be tested. The frictional force is recorded by a load

cell attached to the wear testing machine to find the friction coefficient (

),

which is the ratio of the frictional force (F

f

) and the applied force (F) between

the sliding bodies, i.e. ball/pin and the composite specimen:

μ

F

F

m ¼

½

7

:

8

The volume loss (wear volume) of the specimen is calculated using a

profilometer or measurement of the decrease in weight of the specimen. Wear

rate (W) is calculated by inserting the wear volume (V), sliding distance (L)

and the applied load (F), as follows:

V

LF

W

¼

½

7

:

9

In an unpublished study on model CNT-SiO

2

composites (Subhani, 2012d),

the pin-on-disk technique was used to measure wear volumes and the friction

coefficients of silica glass and 7.5wt% CNT-SiO

2

composites. A hardened

steel (CPM-10V) pin of diameter 36mm slid against the specimen in a

reciprocating motion at a load of 0.15GPa for 60min. A decrease in friction

coefficient from 0.8 to 0.6 was observed on incorporating CNTs in silica glass,

as shown in Fig. 7.17. However, the wear volume of the composite was found