Biomedical Engineering Reference

In-Depth Information

7.2

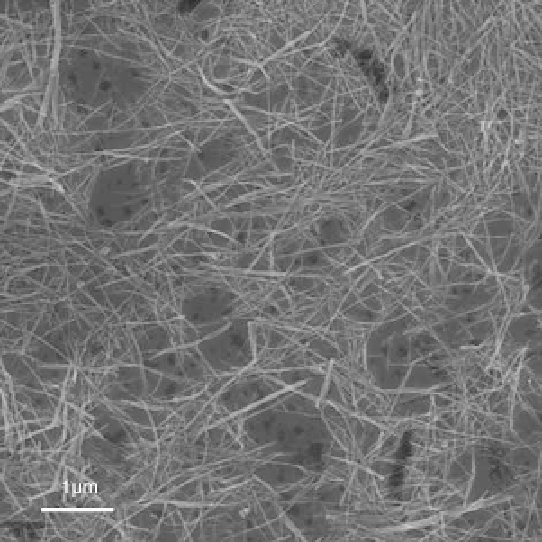

MWCNTs treated with a mixture of sulphuric and nitric acid to

obtain stable aqueous dispersion.

heterocoagulation, which is produced using cationic surfactants, and finally

suitable composite powder suspensions are obtained by colloidal mixing.

The composite powder suspensions are dried, ground and sieved to obtain

powders for subsequent sintering into solid compacts. A calcination process

is usually performed on dried composite powders before sintering to remove

organic surfactants and CNT oxidation debris at temperatures less than

400

C. Figure 7.2 shows an image of MWCNTs after treating with sulphuric

and nitric acid to develop surface charges for stable aqueous dispersion.

In the earliest of these studies, 1wt% CNTs were dispersed in silica glass

(Arvanitelis et al., 2008) but high CNT contents were loaded successfully

(19vol%) in subsequent investigations (Cho et al., 2011). Both pressureless

sintering (PLS) (Subhani et al., 2011) and spark plasma sintering (SPS) (Cho

et al., 2011) have been used to prepare CNT-SiO

2

composites at near

theoretical densities. A uniform distribution of CNTs was obtained in the

silica glass powder, which was retained after sintering. SEM images of 5wt%

MWCNTs composite powder before and after sintering are shown in Fig.

7.3 and Fig. 7.4, respectively. The sintered sample exhibits homogeneously

dispersed CNTs. Individual CNTs are well separated from the others

without showing agglomerates.

8