Biomedical Engineering Reference

In-Depth Information

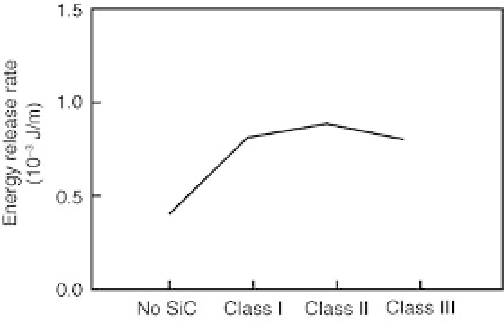

5.11 Mean energy release rate values as a function of microstructure at

loading velocity of 2m/sec. No SiC is a control microstructure with no

SiC particles.

shown to restrict the damage to grain interior. However, SiC particles

primarily determine how soon the structure develops microcracks.

Self-reinforced Si

3

N

4

is an important example of the high-toughness

structural ceramics first manufactured during 1970s. Embedding nanosized

SiC particles in a Si

3

N

4

matrix is one proven approach to improve its

mechanical properties. It is also verified here by comparing the average

energy release rate of all the microstructures with that of a control

microstructure that contains no SiC particles at all (Fig. 5.11). As shown, a

significant increase in the fracture resistance is observed. For the first time,

Niihara [1] reported almost 200% improvements in both the fracture

toughness and the strength of SiC-Si

3

N

4

nanocomposites by embedding

nanometer size (20-300 nm) particles within a matrix of larger grains and at

the Si

3

N

4

GBs. Since then, a number of experiments focusing on

manufacturing SiC-Si

3

N

4

nanocomposites have been reported [2, 53]. So

far it has been very difficult to control the processing routes and conditions

to place SiC particles selectively along GBs. However, it is possible to place

second-phase particles in a combination that places them along GBs as well

as in grain interiors near GBs, which may ultimately result in very high

strength SiC-Si

3

N

4

nanocomposites [14]. Such mechanisms have been

observed for other SiC particle reinforced nanocomposites [85, 86].

Figure 5.12 shows stress-displacement plots for atomistic microstructures

M1 to M6 in order to compare the internal stresses when an initial crack is

present in all microstructures with the internal stresses when the initial crack

is absent in all the microstructures. Figures 5.13 and 5.14 show visuals of

crack propagation as a function of total displacement for microstructures

M1, M2, M4, and M6. The results from Figs 5.12 to 5.14 are now

collectively discussed.

As shown in Fig. 5.12(a), microstructures M1 and M2 have the same