Biomedical Engineering Reference

In-Depth Information

3.2

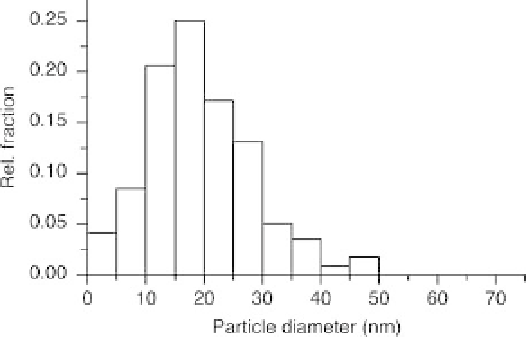

Particle size distribution of a typical poly(ethyleneoxide)-PbS

nanocomposite.

17

attractive for optical studies and applications. The refractive index of some

nanocomposite has been found to depend linearly on the volume fraction of

the particles. When the particles become very small, the refractive index

changes.

17

In optical applications, the refractive index is a key feature.

Typical refractive indices for organic polymers are between 1.3 and 1.7.

8,15

Isotropic refractive indices around 2.1 have also been found (e.g. for poly

(thiophene) or aromatic poly(imide)s

19-21

) and these values are extraordi-

narily high for polymers. The theoretical lower limit of the refractive index

of organic polymers has been estimated to be close to 1.29.

22

So far, an

isotropic refractive index above 2.5 ('ultrahigh' refractive index

23

) or below

1.25 ('ultralow' refractive index

24

) has never been reported for a pure

polymer. Inorganic materials cover a more extended range of refractive

indices (Table 3.1). In technical applications, the refractive index of

inorganic fillers is commonly between 1.4 and 1.7,

25,26

and is occasionally

up to 2.7 (TiO

2

)

25,27

). By incorporating of inorganic colloids with extreme

refractive indices in organic polymers, an attempt has been made to obtain

composite materials with refractive indices outside the typical range of

polymers and hitherto unknown for polymer composites. High refractive

index polymers have many applications, ranging from anti-reflection

coatings for solar cells to high refractive index lenses.

After transmission of visible light through composites comprising a

transparent polymer matrix with embedded particles, the intensity loss by

scattering is substantially reduced for small particles, i.e. particles with

diameters below 50-100 nm (nanoparticles) (Fig. 3.2).

17

Similarly, infrared

(IR) windows are typically made from single-crystal ceramics as single-

crystal windows have excellent optical properties, but they cannot withstand

the mechanical demands of some applications, leading to catastrophic

failures. Ceramic nanocomposites can be used in making IR transparent