Biomedical Engineering Reference

In-Depth Information

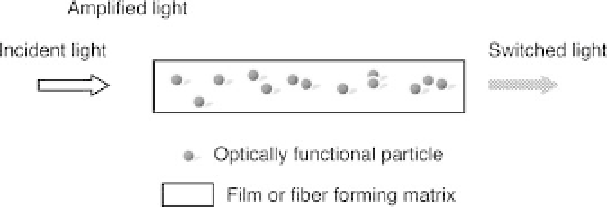

Schematic illustration of optical nanocomposite.

1

3.1

exceptionally high aspect ratio. Nanocomposite materials show great

promise as they can provide the necessary stability and processability for

many important applications. Due to their nanoscale constituents they also

exhibit optical and electronic properties that differ from the corresponding

macroscopic properties. There is a wide range of potential applications of

nanocomposite materials. Among them are electrical and optical sensors,

dispersions, coatings and novel optical glasses.

The applications of optical materials and the need for novel optically

functional and transparent materials are expanding. In addition to optical

needs such as switching and amplification, the materials must be integrated

into existing structures such as waveguides and optical fibers.

1

In general,

the principle in the construction of an optical composite involves the

intimate mixing of optically functional materials within a processable

matrix. This type of composite is schematically shown in Fig. 3.1, where the

enclosing matrix imparts processability in film or fiber forms and the small

particles possess the desirable optical properties.

1

Examples of incorporated phases include quantum-confined semiconduc-

tors, solid-state lasers, small molecules and polymers. Matrix materials can

be polymers, copolymers, polymer blends, glasses or ceramics. Using such a

composite structure, nanocomposites have been formed with non-linear

optical and laser amplification properties, among others.

2,3

In these types of

composites, optical scattering must be avoided; this results from a mismatch

between the refractive index of the matrix and that of the particles.

Refractive index mismatch is not so important in the case of small particles

(typically

25 nm), but for larger particles the refractive index of the matrix

and the particles must be carefully matched to avoid scattering.

1

Since the 1970s there has been considerable progress in the sol-gel

technique for the manufacture of glasses, glass-ceramics and ceramics. This

method has been successfully used for a variety of products ranging from

bulk glasses

4, 15

and optical fibers, to special coatings, ultra-pure powders

and multifunctional materials. The sol-gel processed transparent porous

matrix also offers an exciting potential as a host matrix for doping optically

active organic molecules.

6

This matrix exhibits many properties of inorganic

<