Biomedical Engineering Reference

In-Depth Information

dip-coating

[57,58]

, electrochemical deposition

[59]

, or electrostatic atomization spray techniques

[60]

.

In-vitro

study with rabbit mesenchymal stem cells on nanostructured HA coatings indicated

enhanced osteoblast response and biocompatibility of such surfaces

[61]

. Recent

in-vivo

study in rab-

bits showed increased bone formation on nanoHA-coated titanium implants and significant influence

on early bone formation compared to uncoated implants after 4 weeks of healing

[62]

. These coatings

can be further functionalized with osteoinductive biomolecules.

In-vitro

study with SaOS-2 human

osteoblast-like cells on nanoHA coatings functionalized with collagen by sol-gel technique showed

increased osteoblast activity

[63]

. Silanization using APTES chemistry has also been utilized in cova-

lent attachment of RGD peptide on HA-coated titanium substrates.

In-vitro

study with osteoprogeni-

tor cells isolated from human bone marrow stroma cells showed enhanced osteoblast adhesion and

function on such surfaces

[64]

.

Different forms of calcium phosphate (octa-, di-, tri-, and tetra-calcium phosphate) have been

coated on titanium surface

[65,66]

. Plasma-spraying technique has been utilized to coat calcium phos-

phate on titanium cylinders.

In-vivo

implantation in dog femur and histological evaluation revealed

that these coatings enhanced bone formation with excellent bone-to-implant surface contact

[67]

.

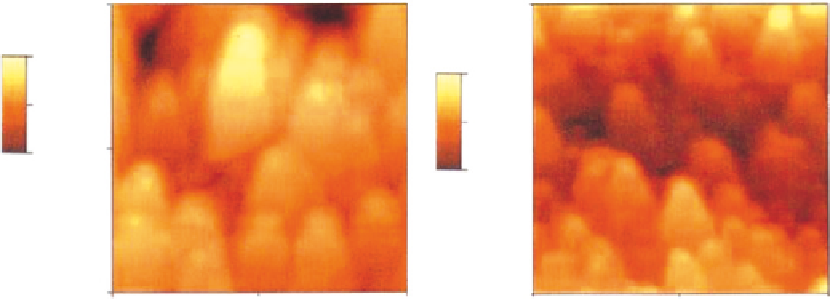

Pulsed laser deposition (PLD) technique has also been employed to fabricate calcium phosphate coat-

ings on titanium substrates (

Figure 6.4

). These types of coatings exhibited much higher adhesive

strength with substrates than conventional plasma-sprayed coatings

[68]

.

In-vitro

study with human

osteoblasts showed that the coatings enhanced osteoblast adhesion, proliferation, and differentiation.

Titanium has also been coated with biphasic calcium phosphate particles using grid-blasting tech-

nique to increase the roughness of titanium implants and enhance the attachment of mouse osteoblasts

and increase the alkaline phosphatase activity

[69]

. A recent approach involved placing of Ti-6Al-4V

discs in concentrated SBF forming a dense layer of amorphous calcium phosphate

[70]

. This layer

served as seeding surface and the discs were placed in supersaturated calcium phosphate solution

that produced a coating up to 100 μm thick. BMP-2, a potent osteoinductive agent, was passively

absorbed on to the coating. The titanium discs with calcium phosphate-BMP-2 coating were implanted

2000nm

2000nm

174nm

76nm

1000nm

1000nm

0.00nm

0.00nm

0nm

0nm

0nm

1000nm

2000nm

0nm

1000nm

2000nm

(A)

(B)

FIGURE 6.4

Atomic force microscopy (AFM) images of the coating surface showing tips of B100nm high (A) crystalline

and (B) amorphous calcium phosphate coatings produced by PLD

[68]

.