Biomedical Engineering Reference

In-Depth Information

However, the milling procedure cannot normally reduce the filler particle size below 100 nm.

Thus, nanotechnology has been used as an innovative way to manufacture fillers from the controlled

growth of an initial molecule (bottom-up approach), resulting in homogeneity in shape and size (in

the range between 5 and 20 nm).

The Filtek Supreme (3MEspe, St. Paul, MN, USA) was the commercial milestone of nanotech-

nology application in operative dentistry in the beginning of this century. This composite resin was

a combination of aggregated zirconia/silica cluster filler with a primary particle size of 5-20 nm and

nanoagglomerated 20 nm silica filler in 78.5 wt%.

Over the last few years, a combination of microhybrid and nanofilled composites has been com-

mercialized. This new combination has increased the filler weight content up to 87% by filling spaces

between larger particles with smaller ones, and has retained optical and mechanical characteristics

which are known to be exclusive to nanofilled composites.

4.5

SEM AND EDS EVALUATION

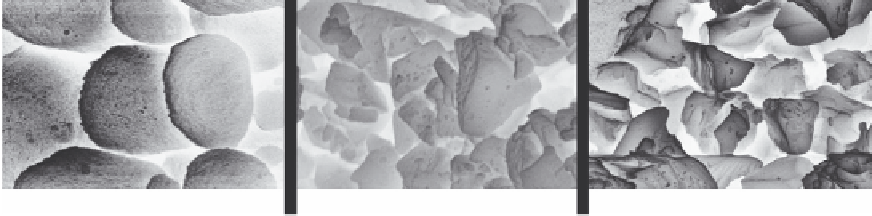

SEM has been used to analyze the shape and size of the filler particles and as a qualitative method to

classify the composite resins

[7]

. Comparative SEM images of nanofilled composites are presented in

Figure 4.3

.

Morphological comparisons show that there are similar patterns between Esthet-X (Dentsply,

Caulk, Milford, USA) and Grandio (Voco, GMBH Cuxhaven, Germany). High amount of irregular

fillers are seen with additional load of small nanofillers around and/or over them occupying the empty

spaces. The same pattern was registered to both enamel and dentin shades. A completely different

pattern can be seen with Filtek Supreme XT (3MEspe, St. Paul, MN, USA) with high amount of

rounded, uniform size fillers in both enamel and dentin shades. Following the classification proposed

by Lutz and Phillips in 1983

[8]

, all evaluated composites could be classified as microhybrid, except

the Filtek Supreme XT which is an exclusive nanofilled composite in accordance to Mitra et al.

[3]

and Beun et al.

[9]

.

(A)

(B)

(C)

1

µ

m

1

µ

m

1

µ

m

P:20.000 x

AMRAY

#0000*

10.0 kV

P:20.000 x

10.0 kV

AMRAY

#0000*

P:20.000 x

10.0 kV

AMRAY

#0000*

FIGURE 4.3

SEM: (A) Nanoclusters of Filtek Supreme XT, the exclusive nanofilled composite. (B) Esthet-X filler, a

microhybrid composite with additional load of nanofillers. (C) Grandio, a high filled microhybrid composite with

additional load of nanofillers.

Source: Hörlle, Hirakata, and Mota (2008).