Biomedical Engineering Reference

In-Depth Information

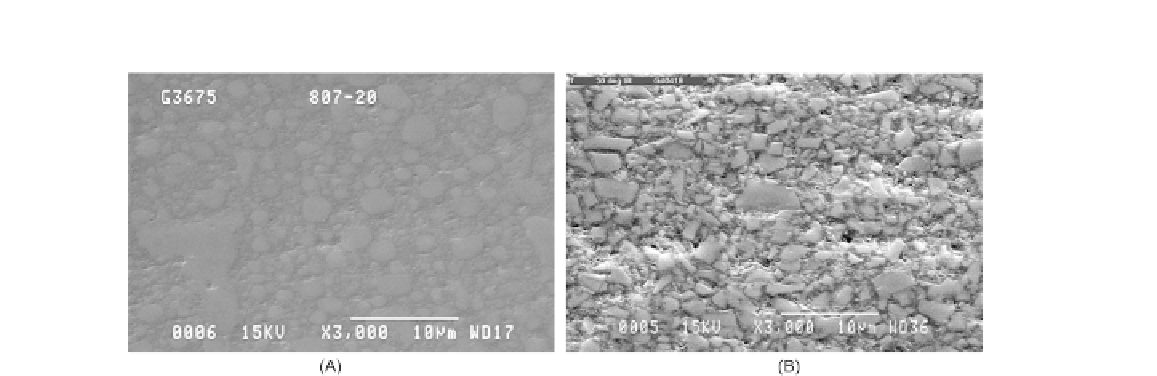

FIGURE 2.6

SEM images of toothbrush-abraded surfaces of (A) a nanofill composite Filtek Supreme and (B) a hybrid

composite Filtek Z250 (3M ESPE Dental Products).

excellent wear resistance. The

in-vitro

wear resistance of the nanofill composite by a three-body abra-

sion test using a modification of the method developed by the Academisch Centrum Tandheelkunde

Amsterdam (ACTA method)

[47]

, Filtek Supreme Plus demonstrated superior wear resistance

compared with conventional hybrid and microhybrid composites

[48]

. The wear facets of the sam-

ples after 117,000 cycles of wear was imaged by atomic force microscopy (AFM) using a Digital

Instruments Dimension 5000 SPM. The nanocomposite sample showed a much smoother wear facet

and roughness compared to conventional composites

[49]

. Cha et al.

[50]

have also reported excellent

wear resistance of the same nanofill composite compared to other restoratives studied using an oral

simulator and a pin-on-disc methodology. Several clinical studies have verified the

in-vitro

results and

are discussed in Section 2.5.

2.4.3

Mechanical Properties

In general the commercial nanocomposites show mechanical properties very comparable to the clin-

ically-proven hybrid and microhybrid composites as reported in several studies.

Figure 2.7

shows

a comparative summary of the results of diametral tensile strength, compressive strength, flexural

strength, and fracture resistance of the nanocomposite Filtek™ Supreme ™ (FSS

standard shades,

FST

translucent shades with several control materials). The values of all the mechanical properties

were equal to or better than the control composites and yet the nanocomposite materials had supe-

rior optical properties versus the comparative materials

[22]

. The spatial and cure-time distribution

of dynamic-mechanical properties of this dimethacrylate nanocomposite was studied by Illie and

coworkers

[51]

. Nano-dynamic mechanical parameters (complex and loss modulus and tan δ) as well

as micro-mechanical properties (hardness, modulus of elasticity, creep, and elastic/plastic deforma-

tion) were investigated. The influence of short- and medium-term immersion in water up to 1 year

at 37°C was comparable for conventional microhybrid composite (Z250) and the nanofill composite

Filtek Supreme. The influence of nano-sized filler particles and nanoclusters materials on the biax-

ial flexural strength of resin-based nanofill and nanohybrid composites has been studied by Curtis