Biomedical Engineering Reference

In-Depth Information

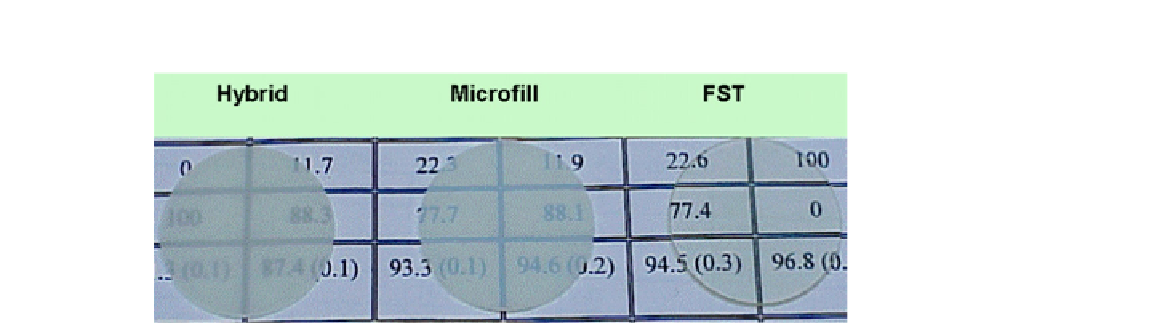

FIGURE 2.5

Optical effect of nanocomposite material FST (Filtek Supreme translucent shades)

versus other types of composites: hybrid and microfill.

can occur, resulting in the formation of pits or voids, leaving a rough, less-polished surface.

Figure

2.6

shows SEMs of toothbrush-abraded surfaces of a nanofill composite (

Figure 2.6A

) compared to

that of a conventional microhybrid composite (

Figure 2.6B

). The difference in surface topography

is readily apparent. In the latter case, the abraded surface is quite rough and shows large particles

protruding from the surface due to the wearing away of the resin matrix and possibly formation of

pits due to loss of filler. On a macroscale the abrasion causes a loss of optical gloss of the composite

which appears dull to the unaided eye. Gloss retention of nanofill composites is much superior to that

of hybrids and microhybrids. The nanohybrids have somewhat better gloss retention than hybrids but

since the optical properties are dominated by the largest particles present in a system these are not

much better than microhybrids and are inferior to true nanofill composites. In a study reported by

Craig and coworkers

[44]

, cured composite blocks of a commercial nanofill composite, two nanohy-

brid composites, and a microhybrid composite were subjected to 6,000 strokes of toothbrush abrasion

under controlled load. Gloss of the samples initially and after the abrasion was measured using a

microtri-gloss meter at 60° observation angle. Although after initial polish all composites exhibited

high gloss, the nanofill composites showed significantly higher polish retention than any of the micro-

hybrid and nanohybrid composites studied.

Figure 2.7

shows the results of the gloss retention study

initially and after 6000 strokes. A study by Yap et al.

[47]

investigated the polish retention of aged

composites including a nanofill composite, an oromocer composite, and conventional composites

over a 6-month aging period in distilled water at elevated temperatures. At all time intervals, compos-

ite materials based on oromocer and nanomer technology were significantly smoother than all other

materials investigated

[45]

.

2.4.2

Wear Properties

The wear resistance of dental composites is of paramount importance. Wear of a restoration may

result from physical or pathological conditions. Mastication during chewing of food or bruxism can

cause attrition of the restorative by the opposite dentition and results in the loss of material and ulti-

mately the original anatomical shape. Several

in-vitro

test protocols to accelerate and predict the wear

of dental materials have been developed

[46]

. Typically hybrid composites have clinically shown