Biomedical Engineering Reference

In-Depth Information

80

80

70

70

60

60

50

50

40

40

30

30

20

20

10

10

0

1

2

3

4

5

6

7

0

Cutting time (min)

1

2

3

4

5

6

7

Uncoated bur

Sintered diamond bur

Cutting time (min)

Uncoated bur

Sintered diamond bur

HFCVD diamond bur

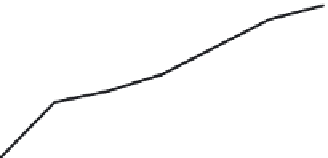

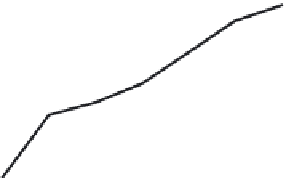

FIGURE 15.32

Flank wear of burs machining acrylic tooth material.

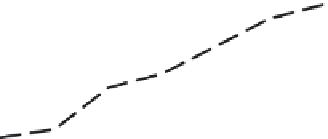

FIGURE 15.33

Flank wear of burs machining human tooth

material.

The teeth were machined using the apparatus shown in

Figures 15.19-15.21

. The life of the burs in the

machining sense was measured by comparing the amount of flank wear exhibited by each type of dental

bur. The flank wear was measured at time intervals of 2, 3, 4, 5, 6, and 7 min machining duration.

Figures

15.31-15.33

show the flank wear measurements for each bur machining different dental materials.

Again, the dental burs were examined using optical and SEM techniques and were found to

observe similar trends as burs associated with drilling experiments close.

15.5

CONCLUSIONS

The teeth reside in a harsh environment and get worn and damaged through prolonged use. In order

to repair damage, add fillings, and implants, a wide range of dental burs are employed by dentists

and dental technicians and these are described briefly. HFCVD process for diamond deposition onto

the burs has been described. The effects of process parameters on the properties of diamond films

and performance of diamond coated and untreated dental burs, such as wear and lifetime, have been

investigated. It has been demonstrated that HFCVD coated burs gave superior performance and

reduced wear compared to uncoated and conventional burs.

References

[1] N.M. Jedynakiewicz, A Practical Guide to Technology in Dentistry, Wolfe Publishing, London, 1992.

[2] R. Simonsen, Dentistry in the 21st Century: A Global Perspective, Quintessence Publishing Co., Hanover

Park, IL, 1989.