Biomedical Engineering Reference

In-Depth Information

(A)

(B)

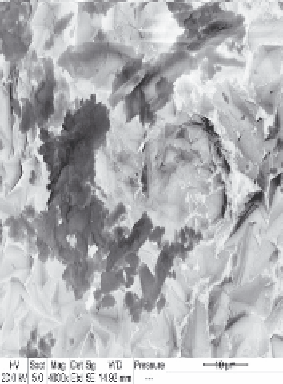

FIGURE 15.29

Magnified image of the CVD diamond-coated dental bur before (A) after

(B) drilling acrylic tooth material.

conducting experiments on acrylic teeth, the mechanisms of wear involves adhesion as well as abra-

sion.

Figure 15.29

shows that inorganic fillers from acrylic teeth adhered to the cutting tool surface in

localized areas when increased rate of abrasion was used.

Natural human teeth were also drilled using a diamond-coated dental bur. Previous studies

have indicated that teeth should not be used for reduction tests because of the differences in hard-

ness between enamel and dentine (Knoop hardness data: enamel, 250-500 kg mm

2

; dentine,

50-70 kg mm

2

). Cuts were made in the central groove of the teeth with the burs.

This permitted cutting three grooves in each tooth.

Figure 15.30

shows the SEM of a diamond-

coated WC-Co dental bur after testing on extracted teeth. It is evident from the micrograph that the

tooth materials such as dentine clog up on the bur reducing its abrasive performance.

An area where this could be important is the surface treatment of small dental tools such as den-

tal burs, which are used in the dental laboratory and clinical surgery for removing unwanted mate-

rial from teeth. The negatively bias-assisted and diamond-coated WC-Co dental burs were tested

with human teeth in order to observe their adhesive strength of diamond particles on the surface.

The coated burs have been tested on extracted human wisdom teeth, which have a difference in hard-

ness between enamel and dentine. The teeth were cut in a bench device using an ultra-high-speed

hand piece (air rotor). A frequency meter monitored the speed of the hand piece, which was between

200,000 and 250,000 rpm. Water-cooling device was used to prevent the tool overheating. The

SEM micrograph of tested dental bur shows that the diamond film was still intact after the applica-

tion of highly abrasive cutting at a speed of 250,000 rpm for 2 min (

Figure 15.30

). These results are

extremely encouraging and clearly demonstrate the extreme toughness and durability of the diamond

films using our modified HFCVD system.

A series of machining experiments were also conducted using uncoated, HFCVD dental burs and

sintered diamond burs when machining extracted human teeth, acrylic teeth, and borosilicate glass.