Biomedical Engineering Reference

In-Depth Information

Work by Wang et al.

[59]

has shown Raman shift of diamond coating can be related to the cobalt

content in the WC substrate. Higher cobalt (10%) concentration of WC-Co dental bur shows com-

pressive stress in the diamond coating. However, in this work it is clear that variations in the film

thickness and crystal sizes are due to variation in the deposition temperature at various positions on

the bur.

15.3.3.2 Effect of Negative BEN on the Dental Bur

A negative bias voltage up to

300V was applied to the substrate relative to the filament using a gas

mixture of 3% CH

4

in H

2

at 20 Torr. This produced emission currents up to 200 mA. The nucleation

times used were between 10 and 30 min. The nucleation density of diamond was determined from

SEMs.

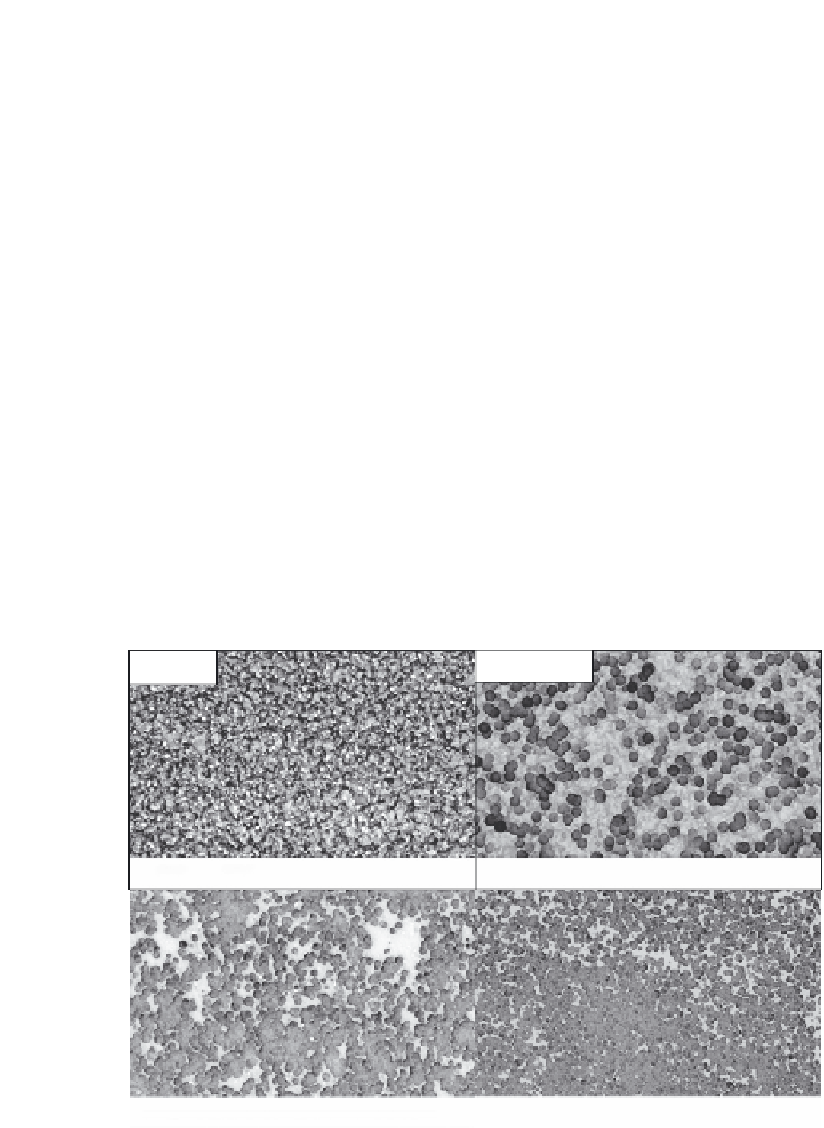

Figures 15.11 and 15.12

show the effects of the substrate bias time on the diamond nucleation

density. It is evident that as the bias time is increased, the nucleation density also increases. The high-

est nucleation density was calculated to be 9

10

9

cm

2

for a bias time of 30 min. At a bias time of

10 min, the nucleation density obtained was 5

10

8

cm

2

.

Figure 15.13

shows the variation of the emission current as a function of the negative bias applied

to the substrate holder where the bias emission current increased rapidly after

180V. Wang et al.

[59]

also reported that an increase in the emission current produced higher nucleation densities. Since

the bias voltage and emission current are related, the enhancement of the nucleation density cannot

be attributed to solely ion bombardment or electron emission of the diamond-coated molybdenum

10 min bias

No bias

20 kV

X3, 500

5

µ

m

20 kV

X3, 500

5

µ

m

30 min bias

20 min bias

20 kV

X3, 500

20 kV

X3, 500

5

µ

m

JEOL

5

µ

m

FIGURE 15.11

SEMs showing the effect of bias time on nucleation density on the WC bur.