Biomedical Engineering Reference

In-Depth Information

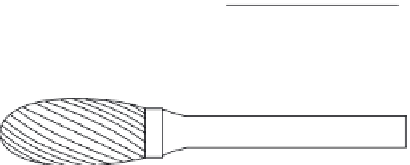

Whole length of bur

lr

lr

Bur

head

Diameter

d

r

d

x

FIGURE 15.2

Dental burs with dimensional parameters showing the bur head

[14]

.

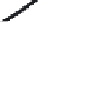

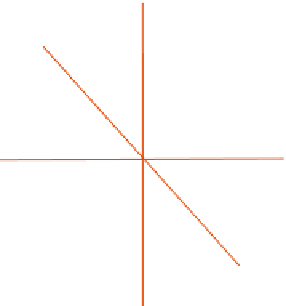

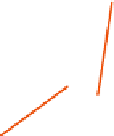

(A)

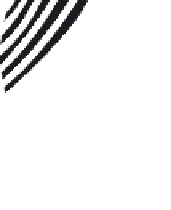

(B)

Rake angle

Direction of

rotation

Clearance

angle

20 kV

X50 500

µ

m

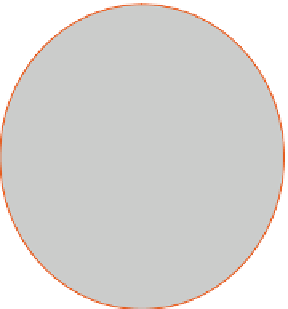

FIGURE 15.3

(A) Geometry of a typical tungsten carbide bur. (B) Schematic diagram showing the rake

angle relative to the cutting direction

[15]

.

The high hardness makes WC extremely wear resistant but it is brittle compared to stainless

steel. Therefore, only the blades of a bur should be made of tungsten carbide and the shank can be

made of steel. Sintering is used to join the carbide blades onto the steel shank. Tungsten carbide

is also suitable for burs designated for use at lower speeds, when they are to be used many times.