Biomedical Engineering Reference

In-Depth Information

15

10

5

0

5

10

15

Width in

µ

m

20

25

30

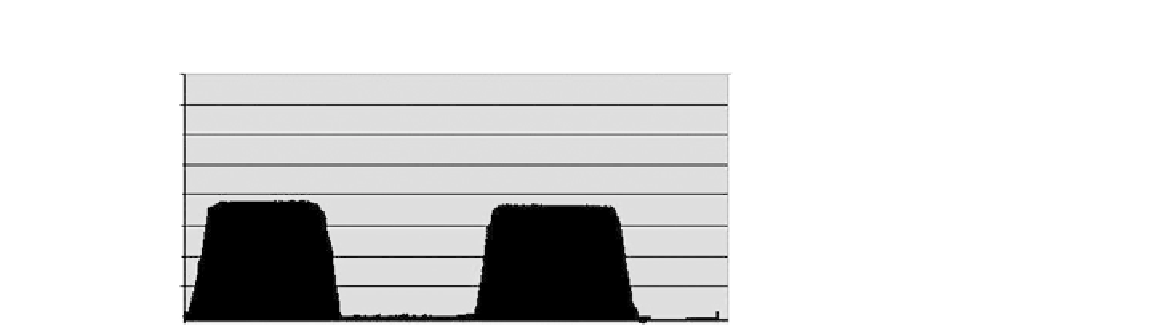

FIGURE 11.8

Surface profilometry showing the height of the PEG hydrogel micropatterns.

Surface profilometry across two walls of the PEG patterns showing height

~7

μ

m and width of 10

μ

m.

to increase in hydroxyl groups over the silicon substrate. Further treatment with TPM resulted in

silanization of the silicon substrate. As described in

Figure 11.5

, silanization of the silicon substrates

resulted in formation of a silane monolayer which acted as coupling agent of PEG hydrogel with

the substrate. The height of the PEG hydrogel micropatterns was measured with a Dektak surface

profiler (Veeco instruments). The height of these hydrogel patterns varied from 5 to 10 μm (

Figure

11.8

). The width of these micropatterns was 10 μm in the microsquares, microcircles, microgrooves

and diamond-like patterns. A variety of other shapes like microtriangles and microhexagons of 10 μm

in width and microstars and cross-shaped micropatterns of 40 μm in width were fabricated as depicted

in

Figure 11.9

.

The use of PDMS was based on pressure-moulding technique of the spincoated PEG hydrogel on

a silicon substrate. The use of PDMS stamp was effective in producing PEG hydrogel micropatterns

of features lesser than 50 to 10 μm. Photopolymerization through the PDMS stamp resulted in fabri-

cation of PEG hydrogel micropatterns of subcellular dimensions (10-40 μm) and sharper resolutions.

In addition, (E) triangle, (F) hexagon, (G) star, and (H) cross-shaped micropatterns were also fabricated

(

Figure 11.9

).

Soft-photolithography technique has several advantages over photolithography technique as it is

relatively inexpensive, simple, and PEG micropatterns of subcellular dimensions with better resolu-

tion were fabricated. The use of PDMS-based elastomeric stamp to produce microstructures of sub-

cellular dimensions (10-40 μm) can be modified by the use of lower molecular weight PEG monomer

and alternative techniques like capillary force lithography

[29]

where a moulding process by capillary

force has been utilized for fabrication of PEG hydrogel microstructures. Along with use of PDMS for

the fabrication of the PEG hydrogel micropatterns, it can also be used as a stamp for patterning extra-

cellular matrix proteins like fibronectin or collagen onto the silicon substrate during capillary force

lithography technique resulting in PEG hydrogel microstructures imprinted with extracellular protein

patterns. This will provide a unique environment for the cells to migrate and proliferate under the