Biomedical Engineering Reference

In-Depth Information

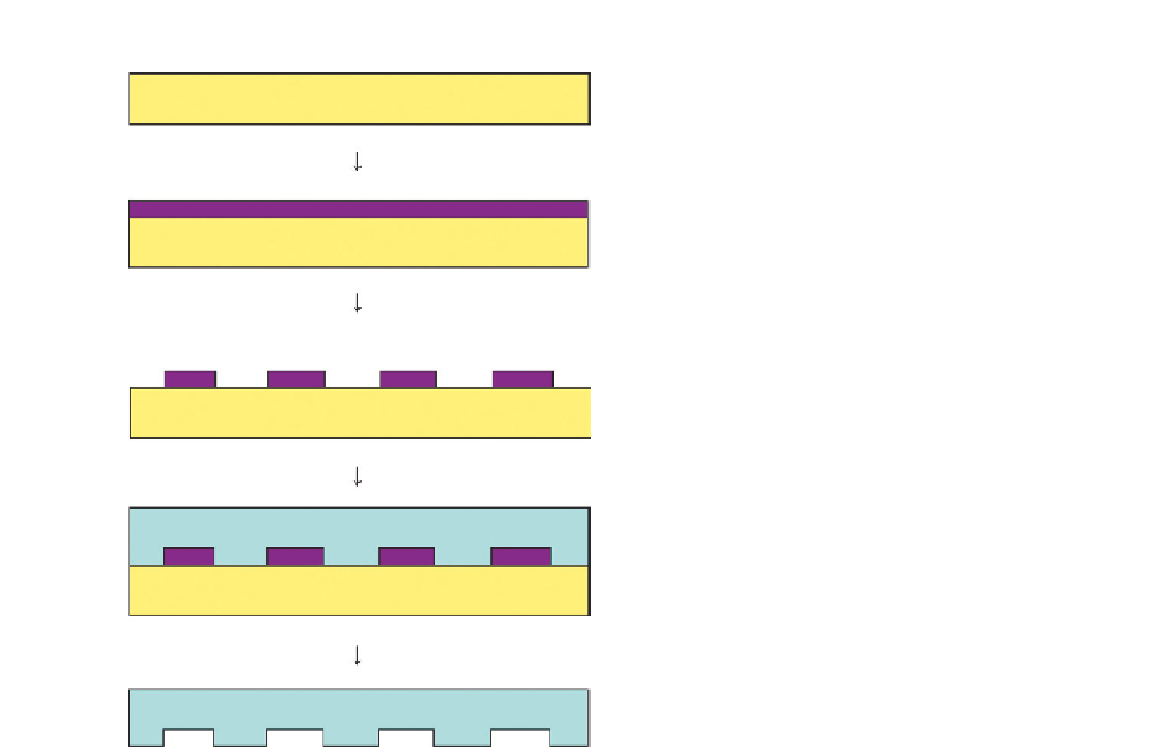

Si wafer

Spincoating of photoresist

Si wafer

Negative mould fabricated by exposure to UV light

through a photomask and developed in a developer solution

Si wafer

PDMS cast over the negative mould

PDMS

Si wafer

PDMS stamp removed from the mould

PDMS

FIGURE 11.3

Schematic illustrations of procedures done for the

fabrication of PDMS stamp.

protective safety clothing were used while handling the piranha solution. After 10 min the silicon sub-

strates were removed from the piranha solution and thoroughly rinsed with deionized (DI) water and

dried under nitrogen. Surface functionalization of the borosilicate glass and silicon substrates with

the silane solution was done by immersing them overnight in 20% (v/v) of TPM and 80% (v/v) of

1,1,1-trichloroethane solution (

Figure 11.5

). The silanized silicon substrates were removed from the

silane solution and rinsed thoroughly with 1,1,1-trichloroethane solution to remove the excess silane

molecules from the silicon substrates and thus ensuring the presence of a silane monolayer. The sili-

con substrates were then dried under nitrogen.

11.5.3

Soft-Photolithography

PEG-DA precursor solution (MW575) was prepared by adding 10 mg of 2,2

-dimethoxy-2-

phenylacetophenone (DMPA) (photoinitiator) to 10 ml of each PEG monomers (1% w/v). DMPA