Biomedical Engineering Reference

In-Depth Information

electrospun PLLA/MWCNTs/HA membranes. This new type of membrane showed excellent dual

biological functions and satisfied the requirement of the GTR technique

[109]

.

10.4.1

Fabrication of PLLA and PLLA/HA Composite Nanofibers

The two-solvent system was exploited to obtain a spinnable PLLA/HA dispersion

[97-99]

. HA nan-

oparticles (

Figure 10.1

) were dispersed in 1,4-dioxane to form a suspension, then dichloromethane

and PLLA particles were added to the suspension, and the suspension was homogenized by using

ultrasonic vibrator. The suspension was then electrospun at fixed parameters: voltage

10 kV, injec-

tion rate

1.0 ml h

1

, PLLA concentration

6 wt%, distance

100 mm, inner diameter of spin-

neret

0.7 mm. The resulted fibrous membranes were placed in a vacuum oven at 50°C over 2 days

to remove the solvent.

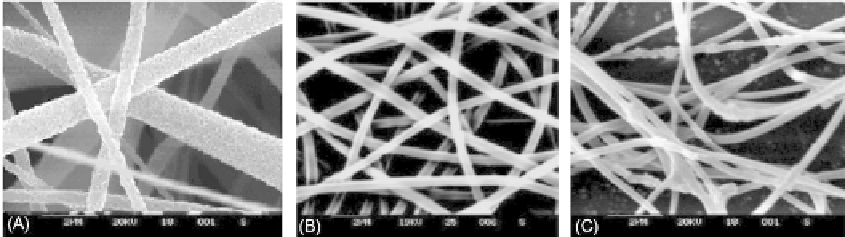

By using different solvent to dissolve PLLA, varied fiber surface morphology would be resulted.

As shown in

Figure 10.2

, the PLLA nanofibers electrospun from PLLA/dichloroform solution exhibited

microporous structures due to fast evaporation rate of dichloromethane. With the addition of dioxane

to slow the fiber solidification, smooth PLLA nanofibers could be obtained. Thus, this mixed solvent

system was applied to electrospin PLLA/HA composite nanofibers, in which, the presence of dioxane

helped to disperse HA particles in PLLA solution and ameliorate the fiber morphology. However, the

incorporation of HA nanoparticles resulted in more beaded in morphology than pure PLLA fibers.

10.4.2

Fabrication of PLLA/MWCNTs/HA Composite Nanofibers

Figure 10.3

shows a schematic diagram of the fabrication progress of the PLLA/MWCNTs/HA mem-

brane. MWCNTs were first modified by anodic oxidation (sulfonic acid/nitric acid, v/v

3/1, 80°C);

then, MWCNTs/HA nanoparticles (3 wt% MWCNTs) were in-situ synthesized by a wet method with

Ca(NO

3

)

2

·4H

2

O and (NH

4

)

2

HPO

4

(Ca/P

1.67) by using an ultrasonic sonicator. The needle-like HA

particles were about 40-70 nm in length and 15 nm in diameter, and well-combined on the surfaces of

anodic oxidized MWCNTs. The prepared MWCNTs/HA nanoparticles were washed with 1,4-dioxane

repeatedly to remove the water and dispersed again in 1,4-dioxane to form a suspension. Dichloromethane

FIGURE 10.2

Choice of solvents on the morphology of electrospun PLLA and PLLA/HA nanofibers: (A) PLLA in

dichloroform, (B) PLLA in dichloroform/dioxane, (C) PLLA/HA in dichloroform/dioxane.