Biomedical Engineering Reference

In-Depth Information

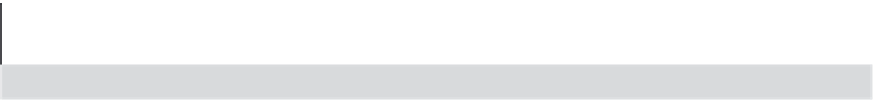

Table 8.2

Methods for Creating Nanofeatures on Ti Implants Using Inorganic Materials

[24,35-40]

Methods

Characteristics

Physical approaches

Surface chemistry of the implants will not be altered

Compaction of micro-/nanoparticles

Localized only to certain parts of the implant surface

Possible weak bonds between particles and the

implant surfaces

Ion beam deposition

Create nanofeatures on the surface depending on

materials used

Chemical approaches

Surface chemistry of the implants might also be

altered

Acid etching

Often used with other methods

Imparts nanofeatures randomly

Peroxidation

Produces a TiO

2

gel layer

Imparts both chemical and topographical properties

NaOH treatment

Produces a sodium titanate gel layer

Varies both chemical and topographical properties

Can be used to deposit HA

Others

Surface chemistry of the implants might or might not

be altered

Sol-gel (colloidal particle adsorption)

Deposits nanoparticles

Creates a nanoscale thick film consisting of chemical

properties

Crystalline deposition

Deposits crystals to obtain a unique complex

topography

Self-assembly of monolayers

Exposes functional end groups (e.g., RGD) that have

specific functions

Lithography

Impart several microtopographic features on the

surface

Expensive, time consuming

coating method

[37]

. Other nanostructures made of metals such as alumina, titania, and zirconia have

also been deposited onto implant surfaces to provide nanoscale ridges that aid cellular adhesion and

differentiation

[44,45]

. Since the contacts are on the quantum scale, physical interaction between the

nanoparticles and the implant surface has been shown to be very strong

[46-48]

. In addition, nanode-

position of calcium phosphate on acid-treated titanium has been shown to significantly increase

mechanical interlocking with bone and accelerate healing of bone tissue

[49]

. Major concerns with

this method include the agglomeration of nanoparticles during the coating process and the uneven

distribution of nanoparticles onto the Ti implant surfaces, especially when nanoparticles are used at

high concentrations.

A modern approach to creating topography on titanium implants is the use of photolithography.

However, this method is expensive, time consuming, and requires considerable development prior to

actual use. Additionally, photolithography is rarely used to create nanoscale structures and mostly