Biomedical Engineering Reference

In-Depth Information

Acc.V

Spot Magn

Det WD

2

µ

m

Acc.V

Spot Magn

Det WD

2

µ

m

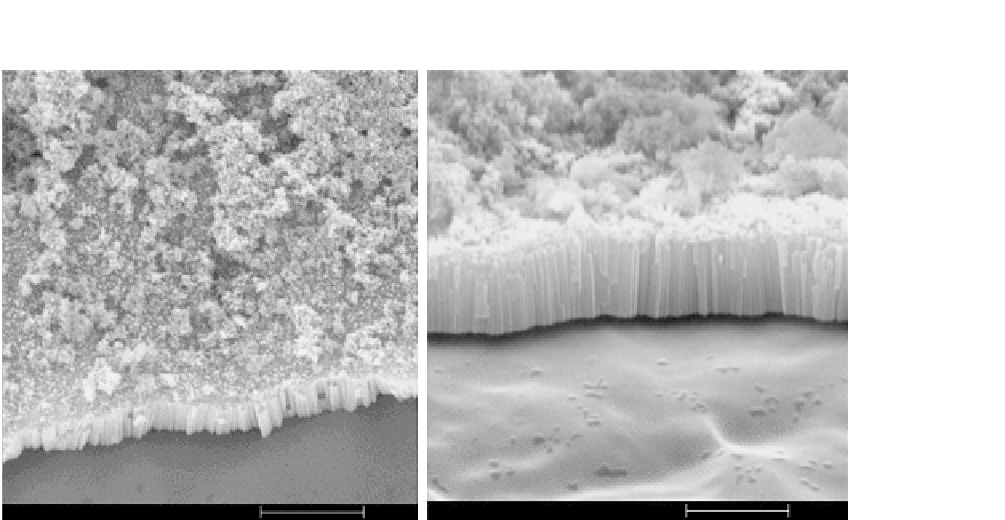

FIGURE 7.5

SEM image showing self-organized oxide nanotube layers grown cp-Ti titanium surface. Anodization

for 30 min using ethylene glycol electrolyte at 30 V and treated with 20 cycles of alternating immersion

in saturated Ca(OH)

2

and 0.02 M (NH

4

)

2

HPO

4

resulted in nanotubes covered with calcium phosphate

crystals. Nanotubes—100 nm in diameter.

Peri-implant bone formation and bone-implant contact (BIC) evaluation revealed that the nanotubular

surface influenced bone formation and development by enhancing osteoblast function and the nanotube

coatings resisted shearing forces evoked during implant insertion. Recently, an

in-vivo

study in rabbit

tibia on bone bonding of two titanium implant surfaces with TiO

2

nanotubes and TiO

2

grit-blasted sur-

faces has been conducted. After 4 weeks of implantation, pull-out testing indicated that TiO

2

nanotubes

significantly improved bone-bonding strength by as much as ninefold when compared with TiO

2

grit-

blasted surfaces. Histological analysis revealed greater BIC area, new bone formation, and higher cal-

cium and phosphorus levels on the nanotube surfaces

[43]

.

7.5

CONCLUSIONS

Anodization of titanium has been effectively applied to fabricate nanotubular surfaces which closely

mimic the nanoscale architecture of human bone. Such surfaces can be fabricated for implant appli-

cations and thus serve as an effective carrier for osteoinductive growth factors to promote bone for-

mation and integration. These recent advances in utilizing TiO

2

nanotubes have been evaluated in

preclinical animal studies

[42,43]

with favorable results. Antibacterial and anti-inflammatory drugs

can also be physically adsorbed on such surfaces to produce antibacterial implant surfaces to prevent

infection and inflammation following peri-implantitis.